Yankee Dryers

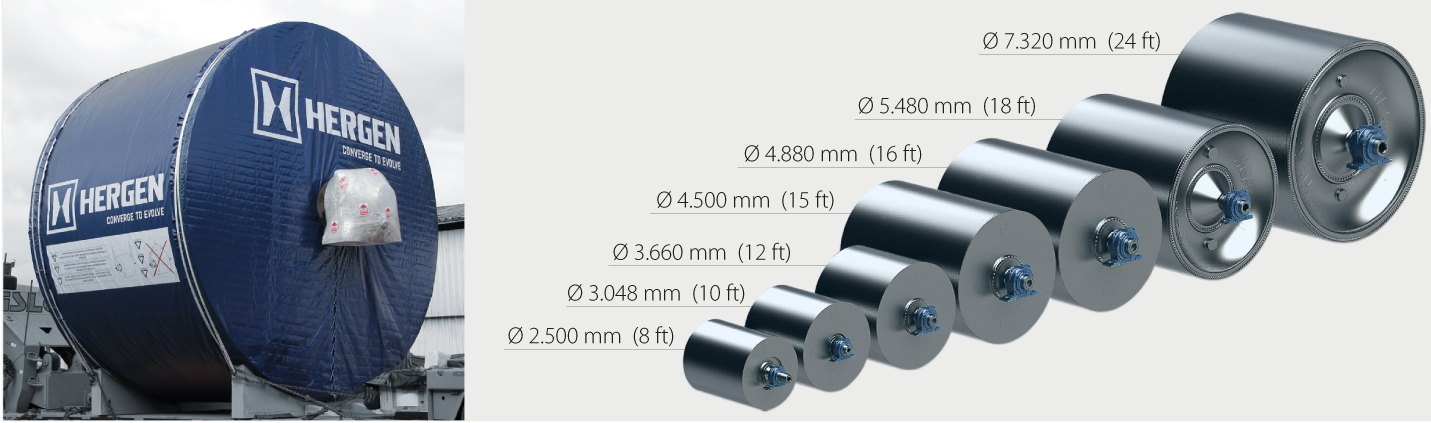

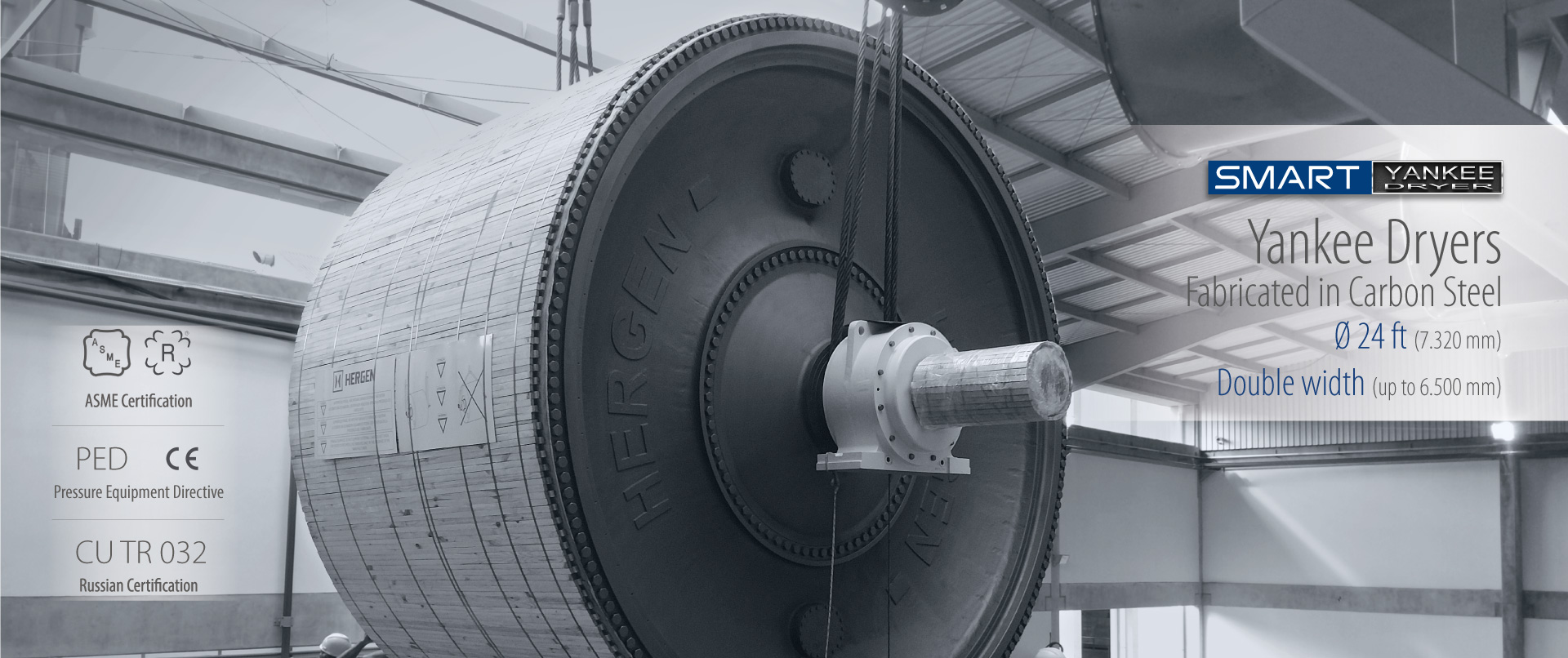

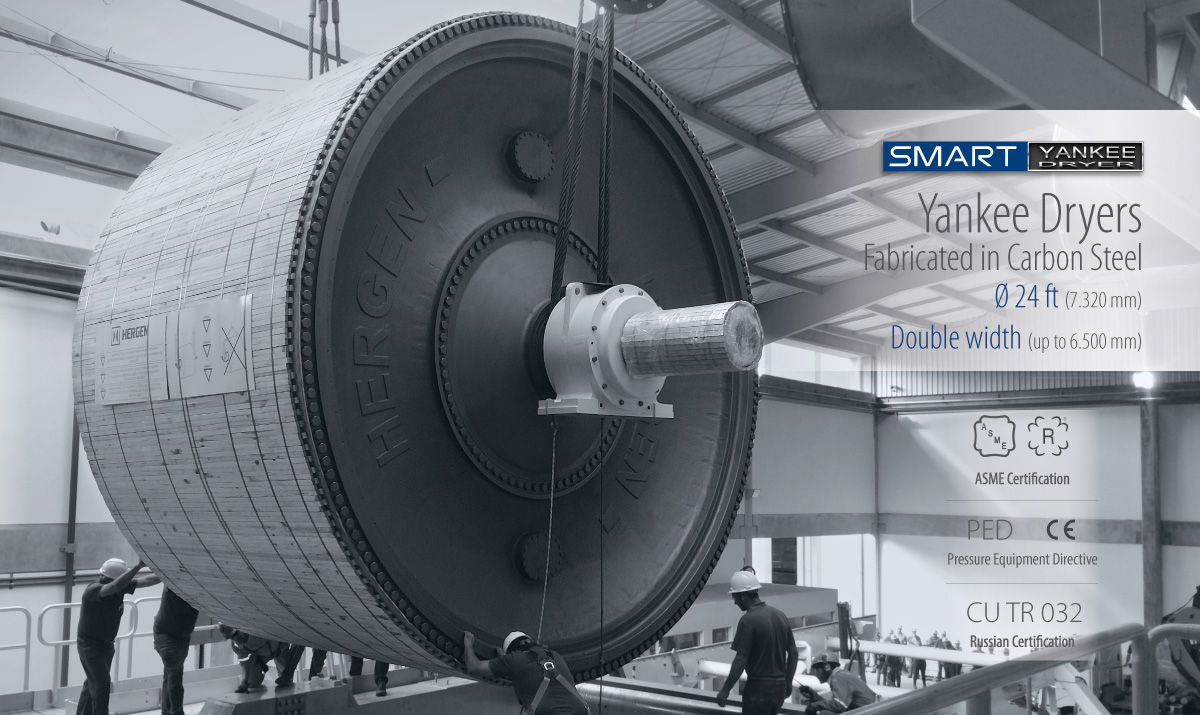

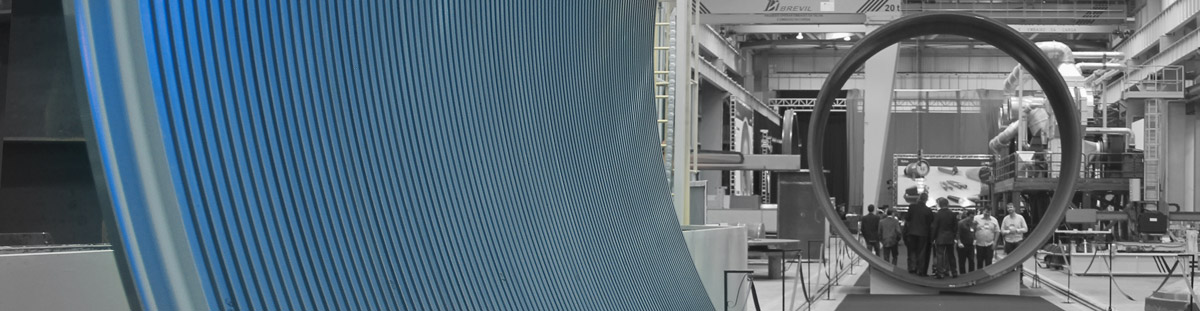

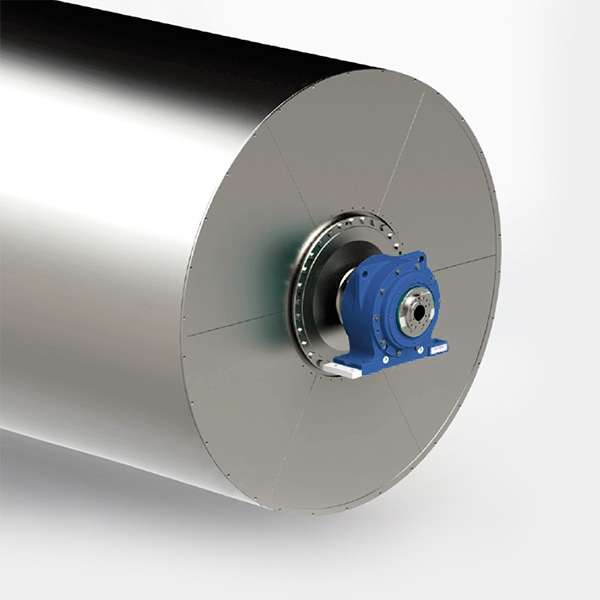

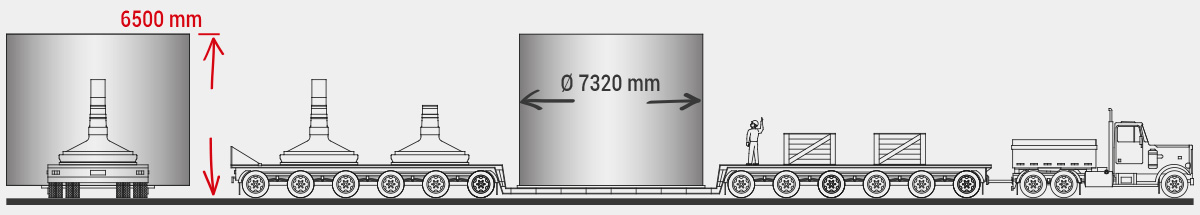

Our Yankee Dryers manufacturing line presents the capability to produce cylinders with diameters up to 7.320 mm (24 ft) and face length up to 6.500 mm.

Therefore, we are now able to attend to any demand from this paper industry segment and definitely have established ourselves in the market as the major supplier of steel Yankee cylinders in Latin America.

We are credited to supply drying cylinders and pressure vessels according to the main international standards such as ASME, PED and CUTR032 (Russia)

Main features

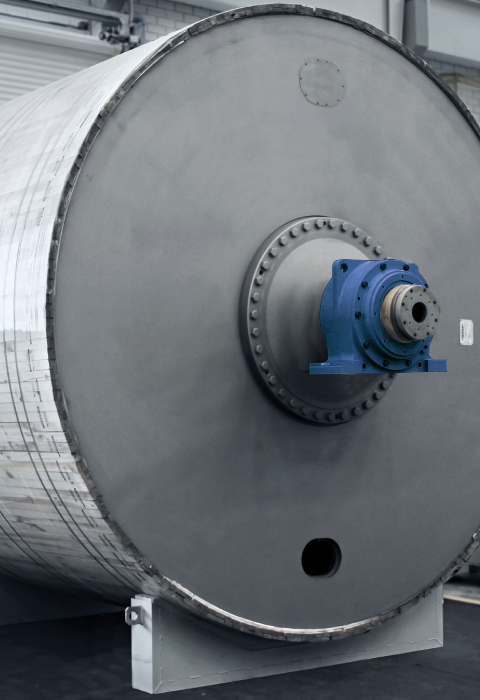

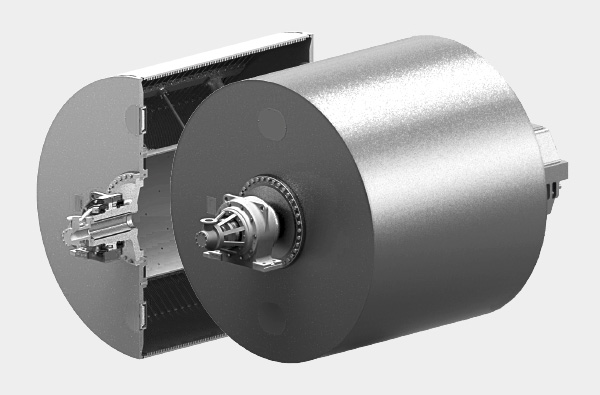

Shell: fabricated with ASME carbon steel plates with high mechanical resistance. All welded joints are totally inspected by means of ultrasonic and x-ray inspections and heat treatment (stress relief).

Head Covers: can be supplied in construction options, bolted or welded to the cylinder shell. All materials are totally controlled by means of ultrasonic inspection and heat treatment (stress relief).

Central stay: manufactured with ASME carbon steel plates. All welded joints are totally inspected by means of ultrasonic and x-ray inspections and heat treatment (stress relief). Steel cast journals with strict control of the physical properties of the materials.

Condensate extractor: designed with multiple soda straws which are manufactured on stainless steel with micro casting nozzle (high hardness). Special system for fixing the straw pipes with easy adjustment of the gap (distance) between nozzle and internal shell surface.

Metal coating: high hardness with a thin layer, which provides a longer YD lifespan enabling high heat transfer.

Manufactured according to ASME North American Code, PED European standard or RUSSIAN Certification.

Cylinders advantages

ZERO explosion risk due construction in carbon steel

Increased production: : Higher heat transfer up to 35% as compared with cast iron cylinders resulting in higher paper evaporation ratio

Innovative condensate extraction system

Higher reliability with no risk inherent to the casting process, such as porosities or discontinuities

Two construction options for Heads: bolted or welded to the cylinder shell

Metal surface with high hardness resulting in better creping quality

Excellent temperature profile

Steel plate allows cylinders construction to cope with any required diameter

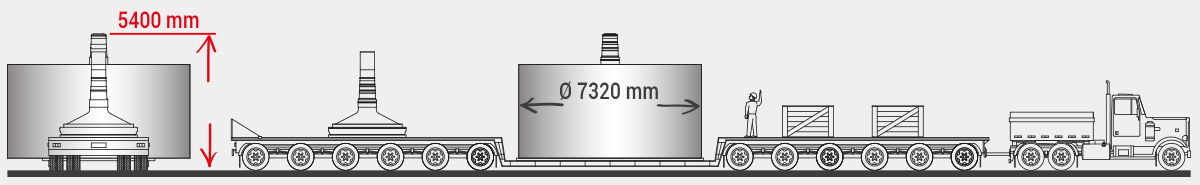

Easy transportation: journals may be transported disassembled thus reducing the maximum load height

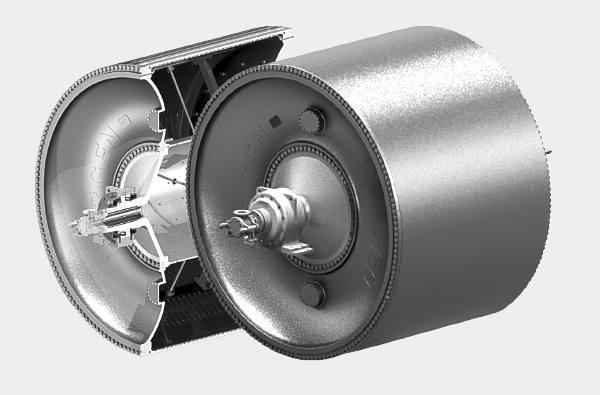

Assembling Features

Welded or Bolted Heads

Welded heads

Bolted heads

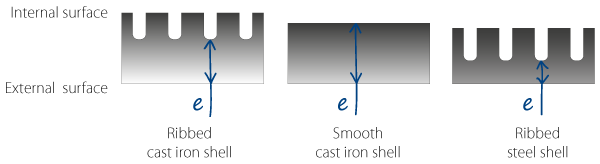

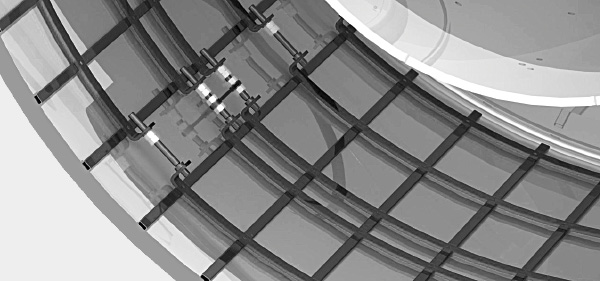

Ribbed or Smooth Internal Surface

We supply cylinders with ribbed or smooth internal surfaces. The ribbed dryers offer more advantages when compared to the smooth surface one. When the ribbed option is combined with the steel construction the benefits are even greater.

Advantages of the STEEL construction with RIBBED internal surface

Due to the mechanical properties of carbon steel plates, shell thickness may be significantly reduced in comparison with a cast iron construction under identical operating conditions

This is an important advantage for a Yankee cylinder since a reduced shell thickness offers less resistance to the heat transference.

When one Yankee cylinder is manufactured with steel plate and in additional is machined with a grooved internal surface, the heat transfer is even greater due to the reduced thickness at the shell root.

Head Thermal Insulation

Dryer cylinder loses heat through its heads which leads to a continuous energy waste. Cylinder thermal insulation minimizes this loss resulting in considerable energy savings

Additionally, thermal insulation also increases operator safety due to the significant temperature reduction on the outside of the insulation

Benefits

Steam saving from 3 to 5%

Increase operator safety

Low cost investment

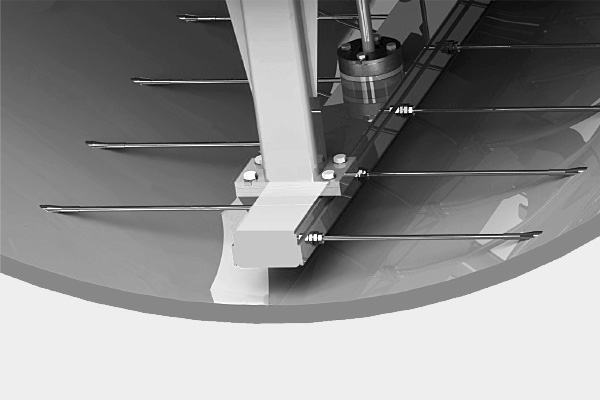

Condensate extractors

The condensate extractors are supported by solid structures which ensure the required frame rigidity.

The entire system is designed to compensate thermal expansion and provide high wear resistance.

For ribbed cylinders

For smooth cylinders

Benefits

Homogeneous condensate extraction resulting in:

• Extremely homogeneous Yankee cylinder temperature CM profile

• Homogeneous cure/maintenance of the organic coating

• High stability of drying and creping processes

• Increased drying capacity

Turbulence Bars

The turbulence bars function is to break the condensate film formed on the inner cylinder surface thus allowing higher convection between the steam and the cylinder for better heat transfer and consequently higher evaporation rate.

Benefits

Increases cylinder drying capacity

Improves drying/moisture profile

Easy installation

Low cost investment

Quality control

Quality certificate for all steel plates used in the manufacturing – mechanical and chemical properties

Quality certificate for cast parts – mechanical and chemical properties and metallographic structure

Cylinder construction in compliance with strict manufacturing standards - ASME, PED, CUTR032 (Russia) - or other standard according to customers requirement

Hydrostatic test in compliance with ASME, PED or CUTR032 (Russia)

Strict dimensional control in all cylinder manufacture stages

Dimensional inspection after cylinder shell manufacturing

Ultrasonic inspection for every shell and cover head

Ultrasonic inspection for all welding seams

Ultrasonic inspection for all bolts

Heat treatment for stress relief

Easy transportation

Journals may be disassembled from the Yankee cylinder. Our team executes journal assembly at the customer’s facility. This makes cylinder transportation easier with considerable reduction of the maximum height

Cylinder diameter 7320 mm and 3700 mm face during transport without the journal on drive side

Cylinder diameter 7320 mm and 6000 mm face during transport without both journals

Manufacturing line