HERGEN installs a new Drying Hood on SWM PM6

December 2, 2024

HERGEN Modernizes IPEL’s PM3

December 11, 2024A great success!

VALPASA Paper Industry, located in the city of Tangará (State of Santa Catarina - Brazil), has reached a working speed of 1,000 m/min on its packaging paper machine, where a new Headbox supplied by HERGEN was installed last August.

“HERGEN is also a part of this achievement, a large part, because the new Headbox was what gave us the opportunity to achieve this record” reports Juliano Cavalca Mayer, Production Manager at VALPASA. “Improvement of the basis weight profile, improvement of formation...we gained a lot with the headbox replacement, greater machine stability” continues Juliano.

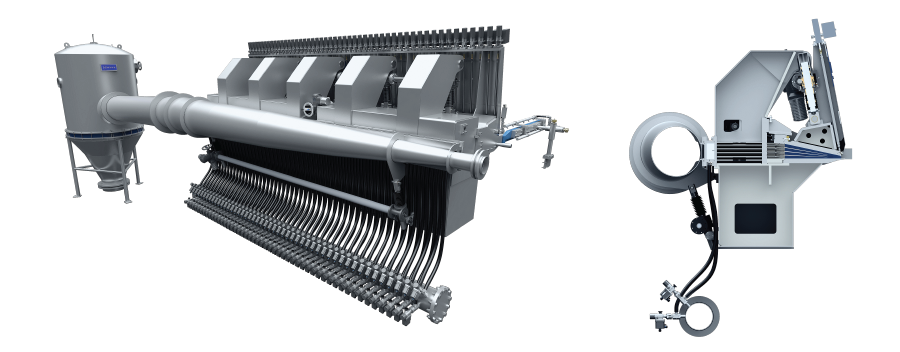

This success story is further proof of the quality of the new iNOVAFLOW Headbox generation, recently developed by HERGEN and which have already produced excellent results, as proven by VALPASA.

This new generation stands out for its mechanical robustness and much better geometric precision. Made from 100% stainless steel, its design is more resistant and less prone to deformation under pressure.

Some Basic Data

BW range: 90-200 g/m²

Paper Grade: Packaging

Production: up to 240 t/d

Design speed: 1.000 m/min

With Side Deckles

With Pulsation Attenuator

Automatic control of the CD basis weight profile (AutoSlice system supplied by Honeywell). In this system, the fine adjustment of the upper lip is carried out automatically, based on the QCS reading

Automatic control of the CD basis weight profile

HERGEN/VALPASA partnership

HERGEN is delighted to receive such positive feedback from its customers, assuring us that we are on the right path, delivering products and services to our partners that meet and even exceed their expectations.

Many thanks to VALPASA for their trust and congratulations on this great achievement! This record shows the competence and dedication of VALPASA’s team.

Valpasa Paper Industry - Tangará, SC

Know more about the new generation of iNOVAFLOW

Modern and stiff concept

This new generation stands out for its mechanical stiffness and much more refined geometric precision. Manufactured in 100% stainless steel, it has a constructive design that is more resistant and less prone to deformations under pressure.

The entire project was conceived based on advanced and highly efficient mechanical concepts designed and certified using the best engineering calculation systems, resulting in a product of excellence and high performance. During the tests, iNOVAFlow's robustness impressed the team, leading them to affectionately nickname it "MuscleHeadBox", in reference to the iconic robust and powerful American cars.

The ergonomic aspects of the new equipment comply with the highest safety regulations, prioritizing safety, and operability.

Flexibility and precision

To meet the specific requirements of each paper manufacturer, another highlight of the iNOVAFLOW is the flexibility to choose the most suitable system for basis weight profile fine tuning.

This new generation can be configured to offer profile adjustment via the dilution system, via transverse deformation control of the upper diaphragm or mixed, where both systems act simultaneously delivering results with very low 2-sigma values across the entire basis weight range.