Drying Cylinders

We fabricate Carbon Steel Drying Cylinders for the whole range of paper machine sizes, through a modern and rigorous manufacturing process, within the highest quality standards demanded by the world market.

We are credited to supply Carbon Steel Drying Cylinders and pressure vessels that comply with the main international certification standards such as ASME, PED and CUTR032 (Russia).

The many advantages of the carbon steel construction

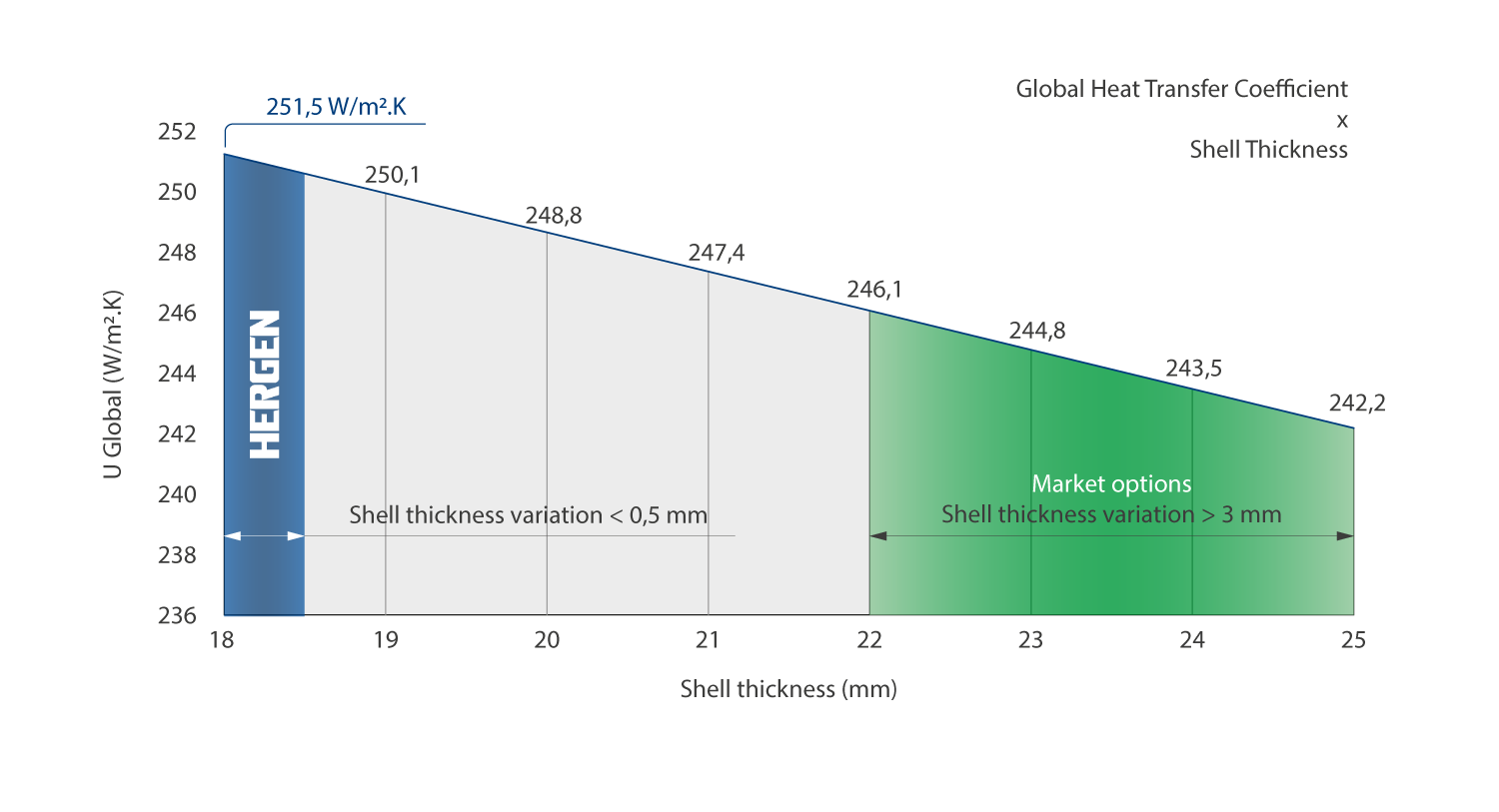

Drying Gain

The main carbon steel property is ductility and this allows the reduction of the shell thickness of the dryer cylinder resulting in higher rates for heating transfer from the steam to the paper web.

The Global Heat Transfer Coefficient of Hergen Cylinders is about 3% higher than the market options

Paper: corrugated

Shell material: Carbon Steel

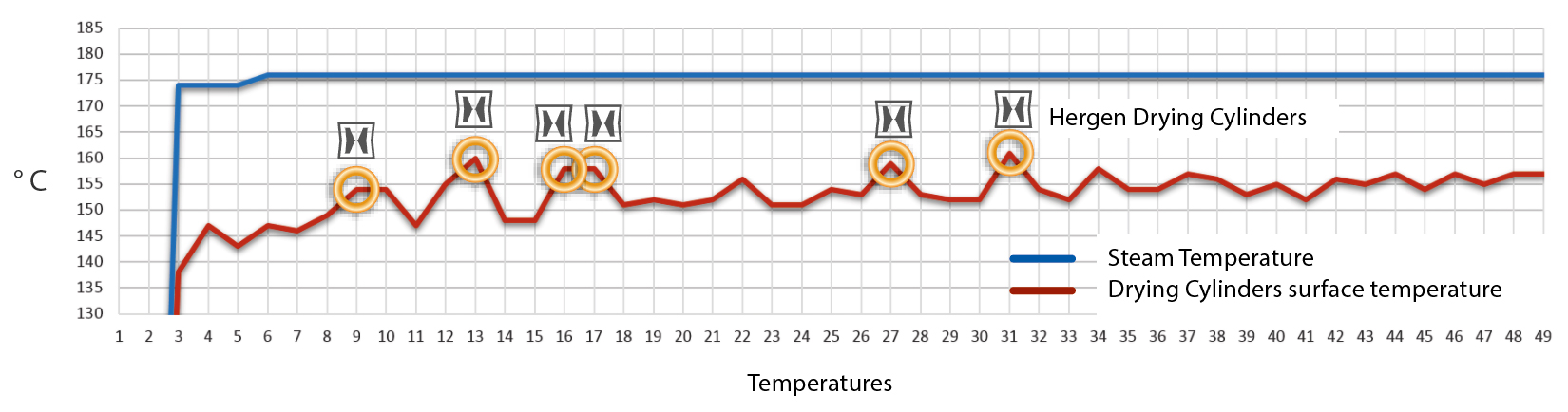

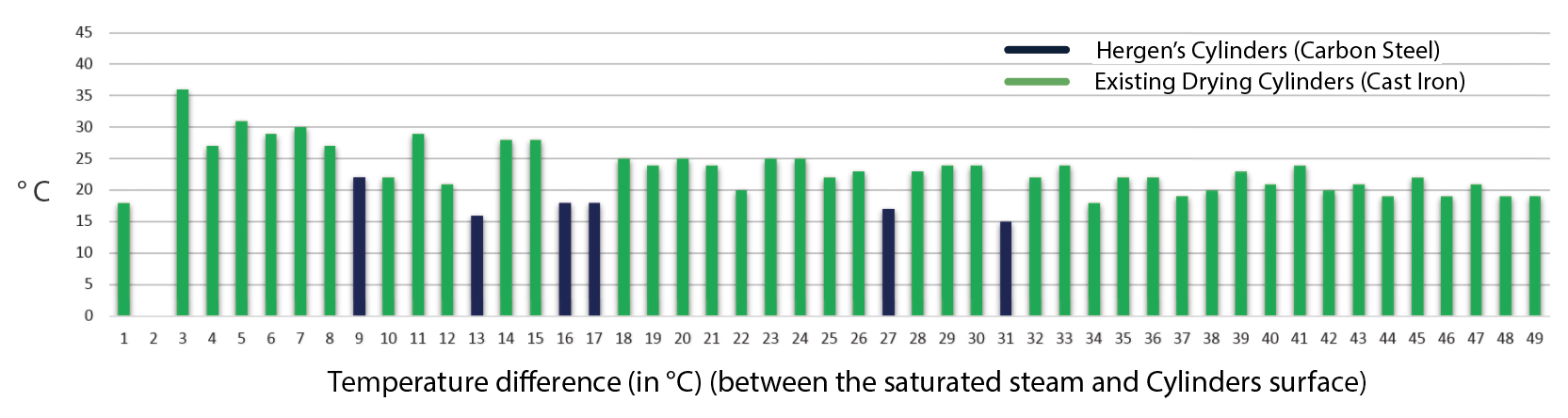

Real-life case:

Six of the 49 old Cast Iron Drying Cylinders have been replaced by our Carbon Steel Drying Cylinders

The Drying Cylinders supplied by Hergen feature a smaller difference between the saturated steam temperature and cylinder surface temperature when compared to the cast iron cylinders.

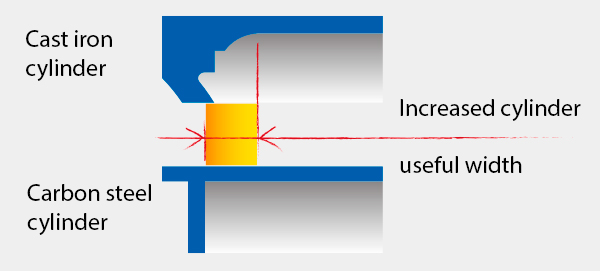

Increase useful width

Due to the compact construction of the steel dryer cylinders, it increases its useful width eliminating wet edge problems during paper drying.

Safety Increase

ZERO risk of explosion due to construction in carbon steel.

Low maintenance

Excellent welding process applied for steel plates eliminating possible leakages.

Cylinder Features

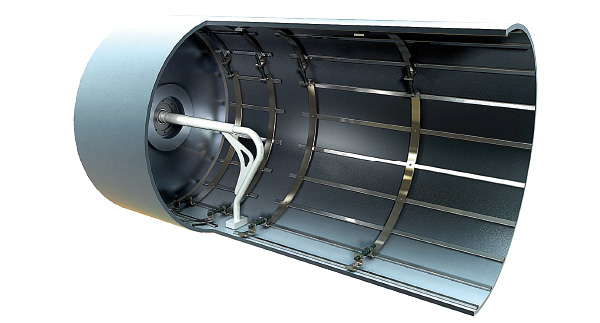

Turbulence bars

Destroy the condensate film created on the inner surface thus enabling higher heat transfer through convection between steam and the inner cylinder surface.

Benefits

Increases cylinder drying capacity

Improves drying / moisture cross profile

Increases evaporation rate for cylinders already running at their evaporation limit

Low cost investment

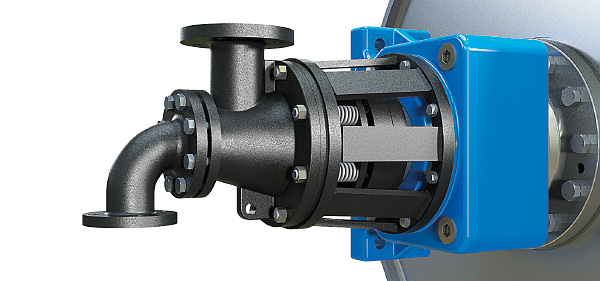

Oil lubricated bearings

Increased roller bearing lifespan.

Reduced maintenance

Excellent cost efficiency

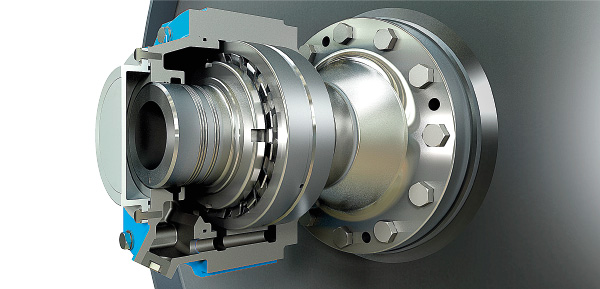

Rotary Joint with flanged assembly.

This allows precise alignment of the rotary joint with dryer cylinder journal reducing seal ring wear

Benefits

Increases seal ring useful life

Reduces maintenance

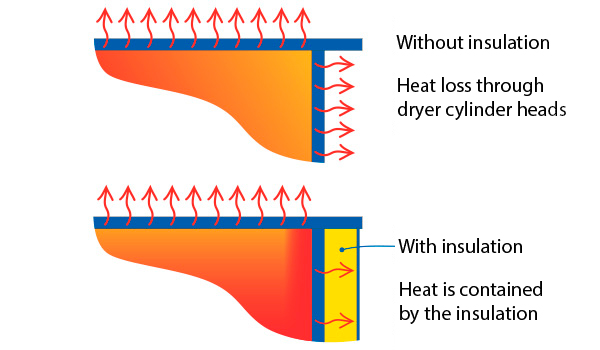

Thermal insulation

Dryer cylinder loses heat through its heads which means a continuous energy waste. Cylinder thermal insulation minimizes this loss resulting in considerable energy savings.

Benefits

Steam saving from 3 to 5%

Increases operator safety

Low cost investment

Quality control

Quality certificate for all steel plates used in the manufacturing – mechanical and chemical properties-.

Quality certificate for cast elements – mechanical and chemical properties and metallographic structure.

Cylinder construction in compliance with strict manufacturing standards (ASME, PED or others, as required).

Ultrasonic inspection for every shell and cover plate.

Dimensional inspection after shell manufacturing.

Ultrasonic inspection for all welding seams.

Thermal treatment for stress relief.

Hydrostatic test in compliance with ASME and PED standards.

Dynamic balancing as per ISO 1940 class G 2.5 Standard.

Thorough dimensional control in all stages of cylinder manufacturing.

Drying Cylinders Line

| Model | Diameter (mm) | Maximum face (mm) | Operating pressure (bar) | Construction Code |

|---|---|---|---|---|

| SSD 1000 | 1000 | 10.300 | 10 | ASME ou PED |

| SSD 1200 | 1200 | 10.300 | 10 | ASME ou PED |

| SSD 1300 | 1300 | 10.300 | 10 | ASME ou PED |

| SSD 1500 | 1500 | 10.300 | 10 | ASME ou PED |

| SSD 1800 | 1828 | 10.300 | 10 | ASME ou PED |

| SSD 2000 | 2000 | 10.300 | 10 | ASME ou PED |

| SSD 2200 | 2200 | 10.300 | 14 | ASME ou PED |

| SSD 2438 | 2438 | 10.300 | 14 | ASME ou PED |