Specialized services

We offer a number of services to old or damaged Headboxes of any brand or design, for packaging or tissue papers machines.

We count on skilled technical personnel to assess each case and provide specific solutions, either executing services at Hergen’s premises or at customer’s site.

Benefits

These services result in advantages such as increased Headbox efficiency, at low investment costs.

Additionally, they allow equipment upgrading, according to the customer needs.

Services we offer

Valuation services: on-site technical survey in order to become familiar with Headbox production and dimensioning data. Having all information available, we develop an assessment and prepare a report containing information regarding the current Headbox behavior, production- and quality-restraining factors, suggestions for improvements, and any other relevant information

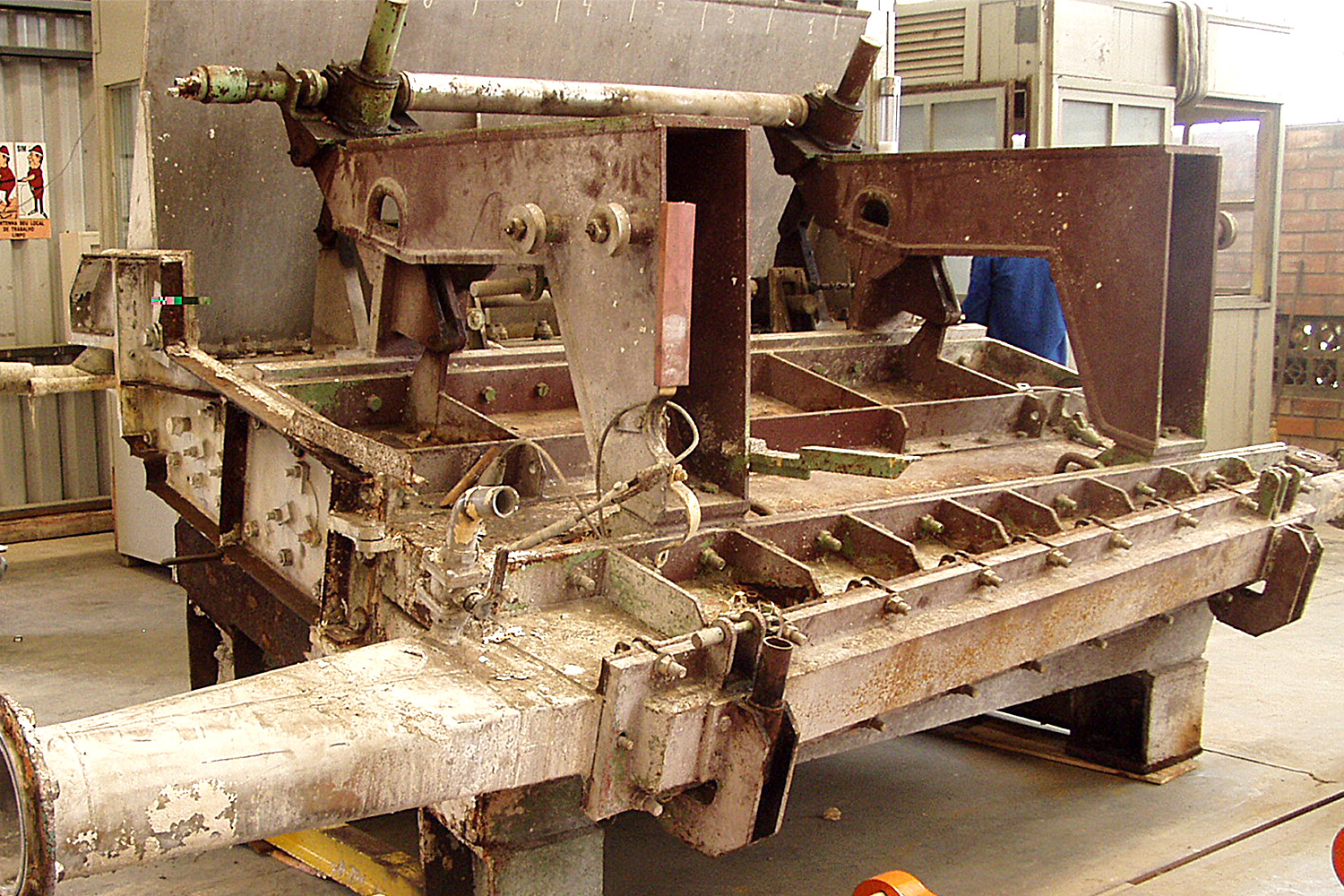

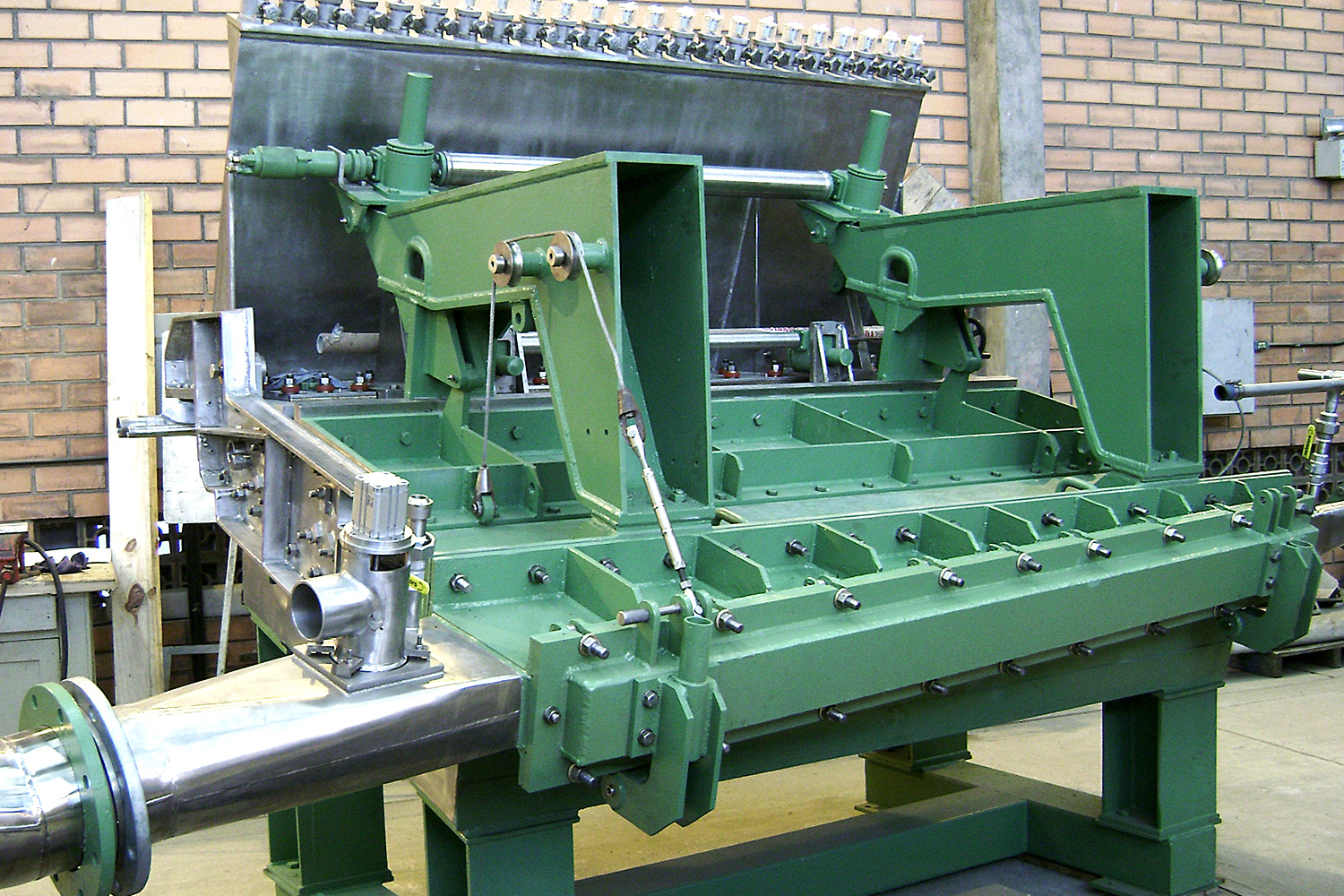

Overhauling: disassembly, cleaning, polishing, lubrication, replacement of worn out commercial components, painting On-site Polishing: after previous evaluation, the on-site polishing service may be executed. This service usually includes main component disassembly, overall cleaning and polishing of the areas in contact with the stock

Lip calibration: every Headbox fitted with top lip micro adjustment system requires lip calibration so that the necessary parallelism between lips is recovered. We offer this service which improves basis weight profile

Lip Grinding: service involving the Headbox top and/or bottom lip grinding. This service is executed at Hergen’s premises. Assembly and calibration are made by Hergen. Disassembly may be carried out by Hergen or by the customer

Lip change: as time passes, the Headbox lips are subject to natural wear and deformations. This affects the perfect equipment operation. We carry out on-site data survey during a machine shutdown period, and supply new lips for any Headbox design