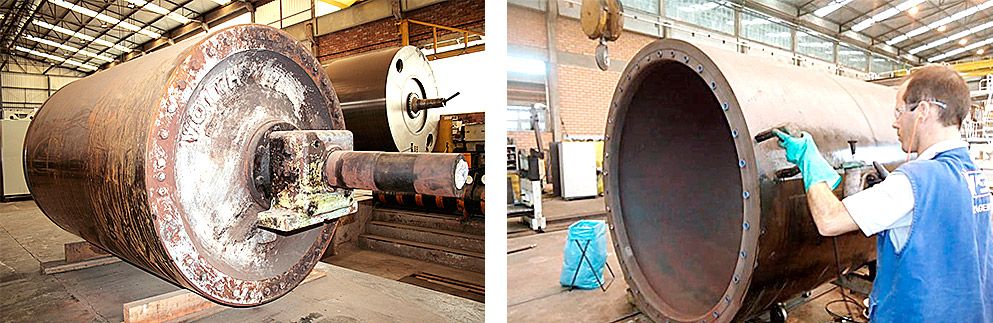

Drying Cylinders

Specialized services

We manufacture Drying Cylinders for more than 30 years. For this reason, we have developed technologies which allow us to offer a variety of services related to these products.

We undertake the overhauling of Drying Cylinders, rehabilitating them for operation in compliance with market standards.

Excellent Cost Efficiency

Customers highly benefit from these services, since they assure improved quality and higher safety to cylinders, at largely lower costs than for new cylinders.

Services we offer

Visual inspection and photographic record of the equipment.

Dimensional inspection prior to overhauling.

Geometrical inspection prior to overhauling.

Equipment serial number certification.

Complete equipment disassembly.

Replacement of old screws by new, high-quality, special screws.

Insulation of cylinder shell / head fits with special seals for up to 10 bar.

Contaminant removal with steel grit blasting.

Hot-water jet cleaning.

Non-destructive test with penetrant liquid.

Ultrasonic non-destructive test.

Magnetic particle non-destructive test.

Pickling of shell faces and heads.

Inspection of threads for cylinder head assembly.

Complete equipment assembly.

Journal assembly with controlled torque.

External cylinder shell grinding 0.80µmRa.

Dimensional inspection after overhauling.

Geometrical inspection after overhauling.

After being assembled, the cylinder is submitted to hydrostatic test according to ASME Code section VIII, division 1 – Pressure vessels – 2015 Edition.

Dynamic balancing as per ISO 1940 Standard, class 2.5.

Cylinder shell external protection with wooden slats.

High-temperature painting

Issuance of technical report containing all information as foreseen by law.