HERGEN attends the International Congress & ExpoAcotepac 2025

February 21, 2025

HERGEN modernizes PM#1 at São Gabriel Papéis

March 7, 2025

Project data

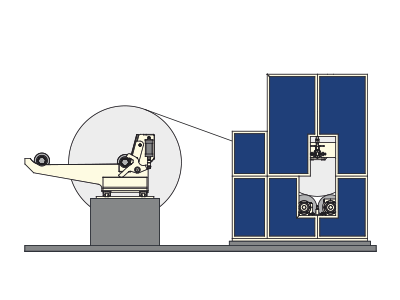

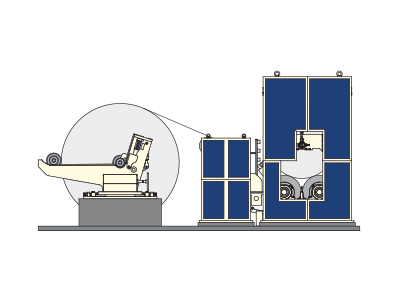

The new Rewinder has been designed to operate at a speed of up to 1,600 m/min, with the capacity to rewind corrugated medium and liner papers, with basis weight ranging from 120 to 270 g/m², with the following roll sizes:

• Jumbo rolls: Ø 2,200 mm x 2,400 mm

• Baby rolls: Ø 1,500 mm x 2,400 mm

The slitting section is equipped with 6 knives and the minimum slith width is 80 mm. The NIP control is hydraulic, guaranteeing greater precision and flexibility in the process.

Results

Shortly after start-up, the equipment has successfully achieved the objectives set for the MP1 upgrade. The Rewinder continues to evolve, progressively adapting to the machine's requirements, while continuous improvements and productivity increases are consistently implemented, highlighting the excellent runnability of HERGEN's Excel line Rewinders.

HERGEN/PANASA partnership

In recent years, PANASA has invested in continuous improvements to its PM1 and PM2 machines. For HERGEN, it has been a great pleasure to establish a long-lasting and trusting partnership with PANASA, achieving success in important projects such as the implementation of new Fabricated Drying Cylinders, new fabric Guide Rolls and new Pope Reels for both, PM1 and PM2.

The installation of the new Rewinder at PM1 is another significant milestone in this successful partnership, aligned with PANASA's growth and innovation objectives.

Find out more about the Excel Rewinders

produced by HERGEN

Fully automated

Fitted with regenerative brake

Automatic sheet threading

Application Header

Transversal Knife

Carton Core Feeder

Safety protections are installed around the equipment and fitted with blocked accesses to avoid Operator entrance while the machine is running

Equipped with all necessary devices to ensure operator safety

Controllers that meet the highest safety standards

Rewinder line

Operating speed: up to 1,500 m/min

Paper width: up to 3,600 mm

Operating speed: up to 2,500 m/min

Paper width: up to 5,200 mm