HERGEN supplies a new Rewinder to PANASA in Ecuador

February 24, 2025

HERGEN delivers the second stage of FEX’s MP1 upgrade – increasing production and sustainability

March 12, 2025

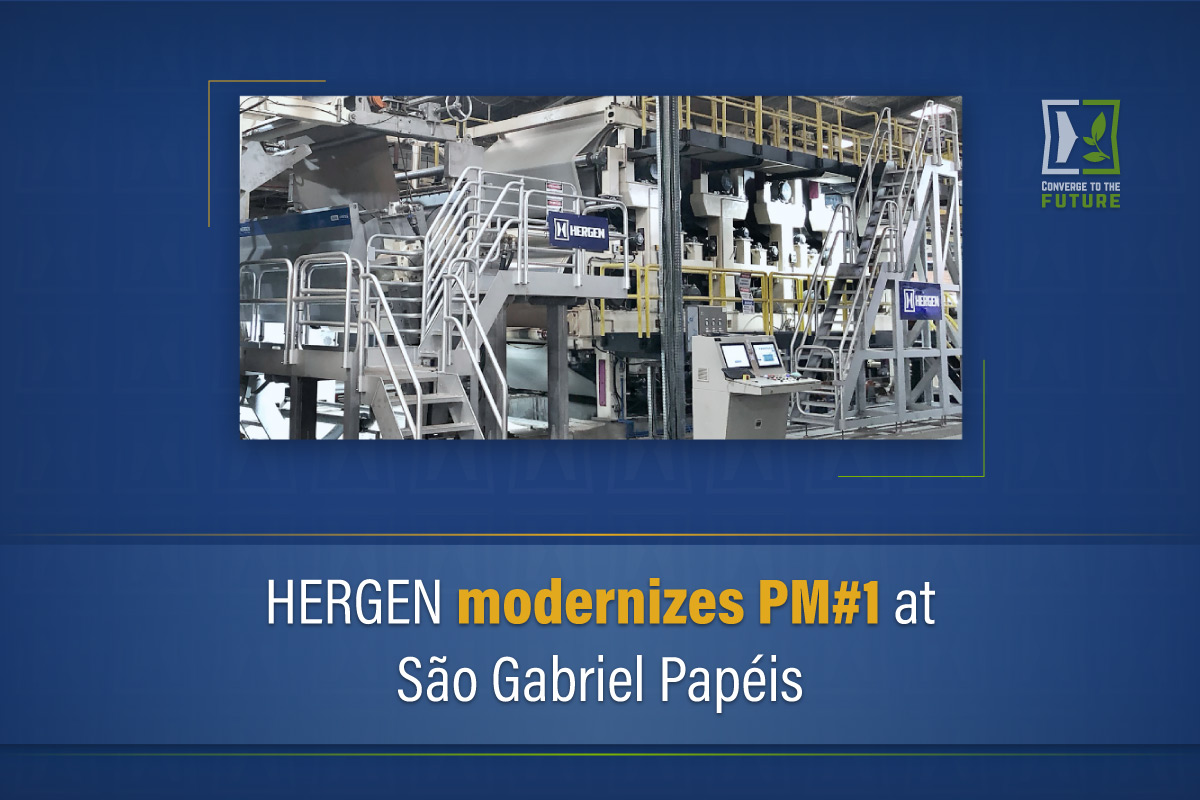

HERGEN has just started-up the a new Size Press and post-drying system featuring a set of Smart Steel Dryers at São Gabriel Papéis' PM#1, located in União da Vitória- State of Paraná - Brazil. This upgrade enabled the production of high-quality paper with lower fiber consumption, with basis weight ranging from 100 g/m² to 180 g/m². The paper width on the Pope Reel is 2,550 mm, and working speed from 450 m/min. to 500 m/min. On this first stage of the project, with the possibility of future expansion to working speeds up to 800 m/min.

The PM#1 performance after the modernization delivered by HERGEN is improving according to plan. During the start-up phase, initial tests indicated stable running and efficient setup, reinforcing the reliability of the project.

With the aim of improving the paper's physical properties, such as strength and thickness, as well as increasing production and focusing on the best return of investment the PM#1 modernization project involves two main areas.

Size Press

The first is the Size Press, which stands out for its applicator rolls with a diameter of 1,000 mm and a frame fabricated entirely of stainless steel. Designed for the hybrid concept, it allows operation with both puddle and application headers (film press). The Hybrid Size Press is a modular machine, which makes it possible to install Smart Sizer Headers in the future, further expanding the application range and production flexibility.

HERGEN’S Smart Sizer (illustrative images)

Post-Drying

The PM#1 also received a new Post-Dryer section, that features 10 Smart Steel Dryers, recognized by the market for their superior heat transfer rates. Fabricated in carbon steel and with welded heads, they have a diameter of 1,500 mm and guarantee uniform and efficient drying, with homogeneous heat transfer and an increase in the useful drying width, reducing the wet edges problem.

HERGEN's Smart Steel Dryers are designed with an exclusive machining process, guaranteeing the best heat transfer rates on the market, resulting in greater productivity and energy savings.

Smart Steel Dryer (illustrative images)

Technology that save resources and boosts productivity

The installation of the hybrid Size Press and Smart Steel Dryers will allow São Gabriel Papéis to combine performance and sustainability, with the following benefits:

Better paper quality

Efficient use of fibers and chemicals

Reduced energy consumption

Reduced CO2 emissions

Less maintenance requirements, with the use of technologies that use durable and sustainable materials

Increased operational safety, in compliance with most strict market standards, and elimination of explosion and steam leakage risks

HERGEN/São Gabriel Papéis partnership

The partnership between HERGEN and São Gabriel Papéis has generated great confidence in the project's results. The expectation is that the RCT (Ring Crush Test) and CMT (Concora Medium Test) will be improved by up to 30%, in addition to a 10% reduction in basis weight. These advances will enable São Gabriel to produce paper of even higher quality, using fewer fibers, which will reflect not only on efficiency gains, but also a commitment to sustainability and continuous improvement in production.

HERGEN would like to thank São Gabriel Papéis for their trust, which has been essential to the realization of this project. In addition, the upgrade project delivered by HERGEN is already preparing São Gabriel's PM#1 for a future increase in capacity and quality, with the possibility to reach up to 700 m/min, which will significantly increase the unit's productivity.

With this investment, São Gabriel Papéis is positioning itself for an even more sustainable and competitive future, aligning innovation and technology with its operations to ensure greater efficiency and quality in paper production.