HERGEN announces the creation of a Professional Training Center to train young talent

August 28, 2025

HERGEN raises quality standards with SMART FLOW Precision Headbox in an international Project

October 8, 2025

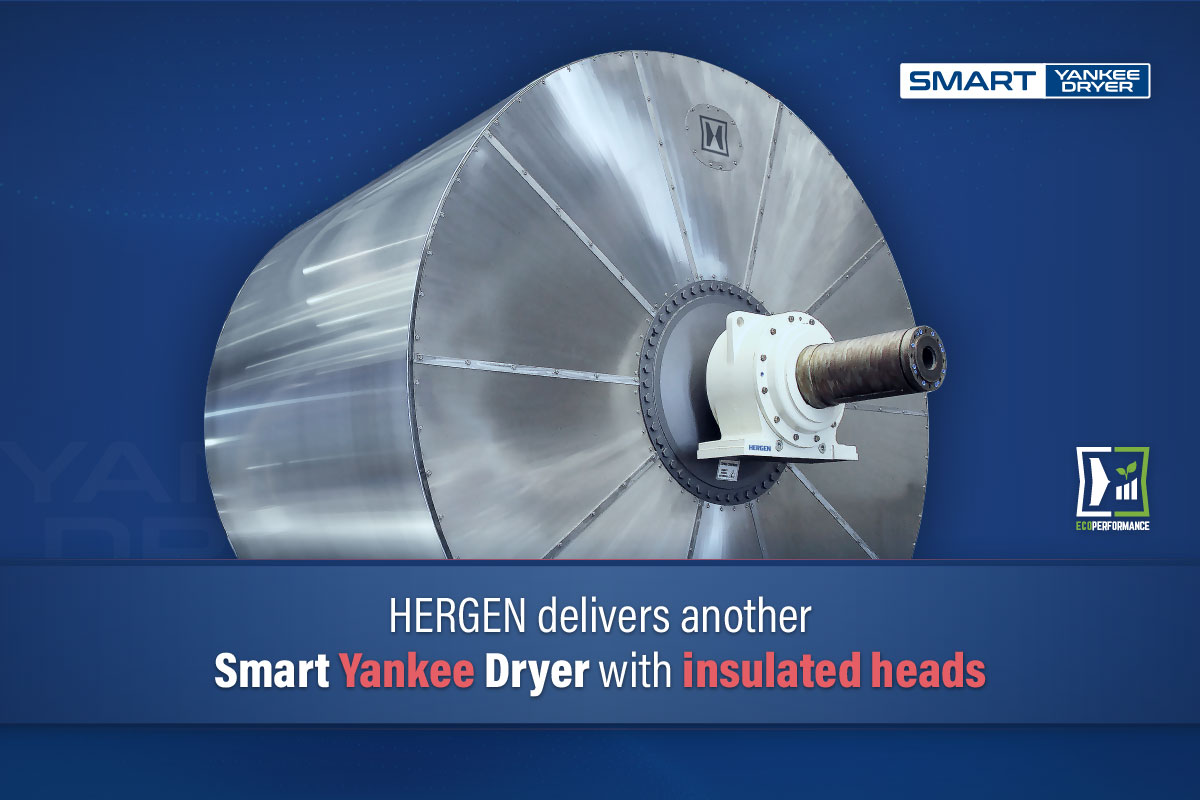

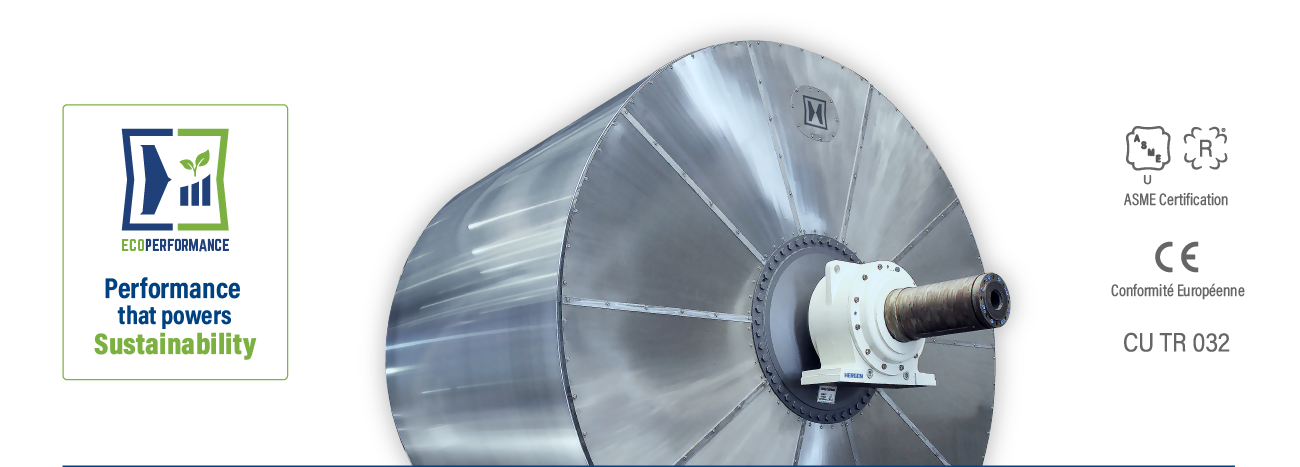

HERGEN has just delivered a new Yankee Cylinder of Ø 4,880 mm (16 feet) and 3,120 mm face length, with a working pressure of 10 bar, to be installed on a new EVO 16 machine. Transported by a special truck, the equipment reinforces the company's presence in the market and expands its reference list for Smart Yankee Dryers with insulated covers.

Recognized in the local market as well abroad for their quality and efficiency, HERGEN's Smart Yankee Dryer Cylinders stand out for their high heat transfer rate, achieving excellent productivity results.

Proven Efficiency

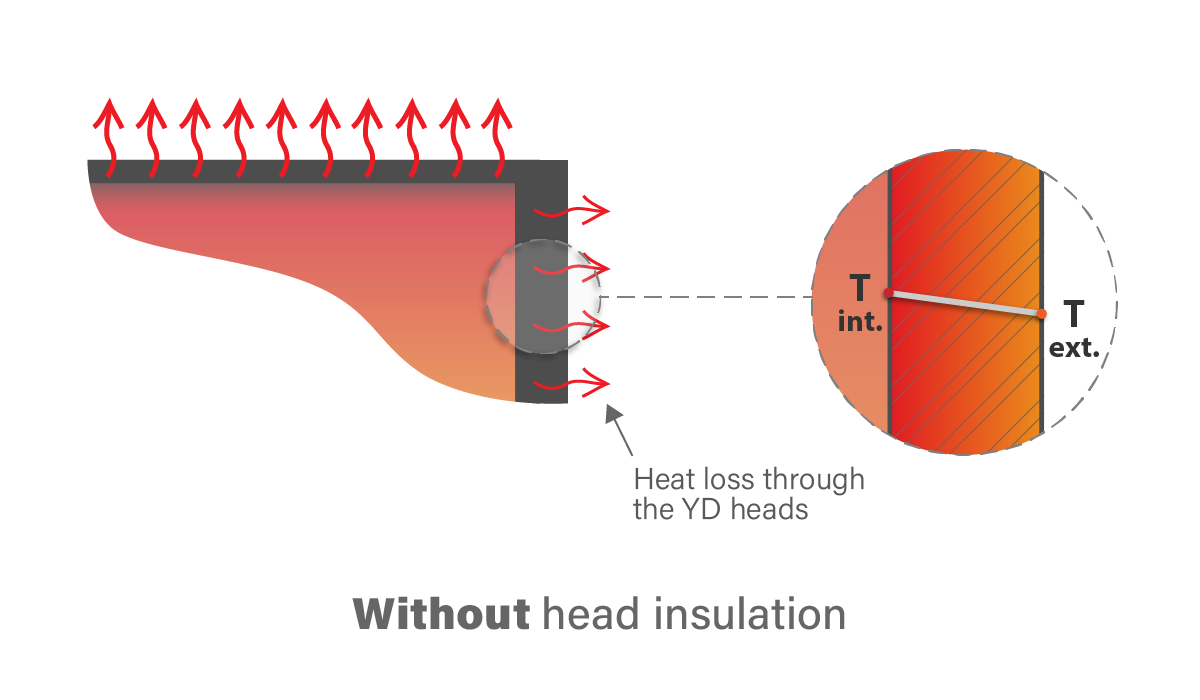

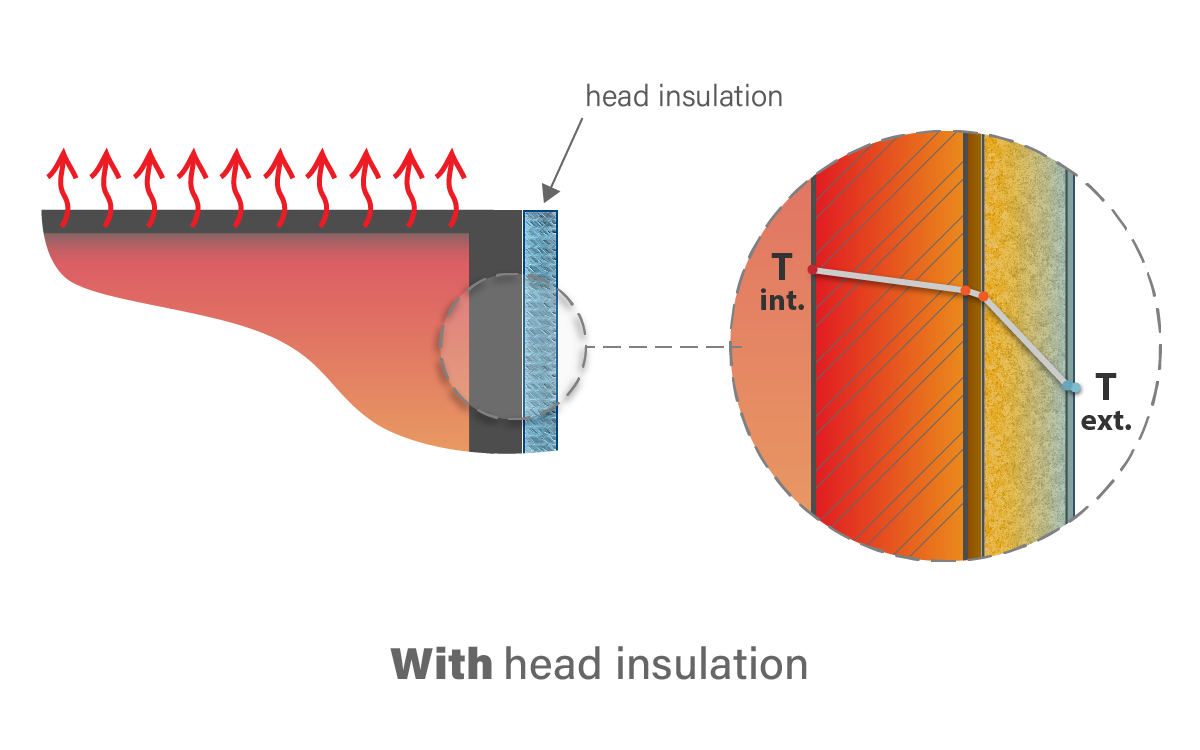

One of the its greater differentials is the heads insulation, which significantly reduces heat losses —which is a natural process in any Yankee Cylinders and that represents continuous energy waste. Field tests show that while the external temperature of uninsulated heads varies between 140° and 150°C, with insulated heads this value drops to only 45° to 55°C.

This efficiency improvement can result in real gains between 3 to 6%, depending on cylinder diameter, which translates into reduced energy (gas, steam, and/or electrical energy) consumption or production increase..

Performance with Sustainability

In addition to insulated heads, Smart Yankee Dryers cylinders are constructed of steel with a grooved inner surface, maximizing heat transfer to the paper sheet and increasing drying efficiency. This superior performance, combined with the savings generated by the insulation of the heads, promotes real gains in productivity and energy efficiency.

More than just economic benefits, this reduction in steam or gas consumption means less burning of fossil fuels and, consequently, lower greenhouse gas emissions. In this way, Smart Yankee Dryers contribute to a more efficient and environmentally responsible production process, aligning technology and sustainability.

Another significant benefit is operational safety: with much lower external temperatures on the insulated heads, the risk of accidents for mill stuff is significantly reduced.

International Quality

The many Smart Yankee Dryers supplied to the global market attest their superior quality and performance. HERGEN is accredited to supply cylinders with the main international certifications, such as ASME, PED, and CUTR032, and has the largest production line of drying cylinders in the Americas.

Thus, the company is prepared to meet virtually any need in this segment of the paper industry and has established itself as the leading supplier of Yankee cylinders in Latin America, offering solutions that combine technology, efficiency, and sustainability.

Learn more about Yankee Dryers

ZERO explosion risk due construction in carbon steel

Increased production: : Higher heat transfer up to 35% as compared with cast iron cylinders resulting in higher paper evaporation ratio

Innovative condensate extraction system

Higher reliability with no risk inherent to the casting process, such as porosities or discontinuities

Two construction options for Heads: bolted or welded to the cylinder shell

Metal surface with high hardness resulting in better creping quality

Excellent temperature profile

Steel plate allows cylinders construction to cope with any required diameter

Easy transportation: journals may be transported disassembled thus reducing the maximum load height