HERGEN moves forward with stages #2 and #3 of IBERKRAFT PM1 modernization project

October 22, 2025

The future of tissue is sustainable! HERGEN presents trends and technologies at the ABTCP Workshop

November 27, 2025

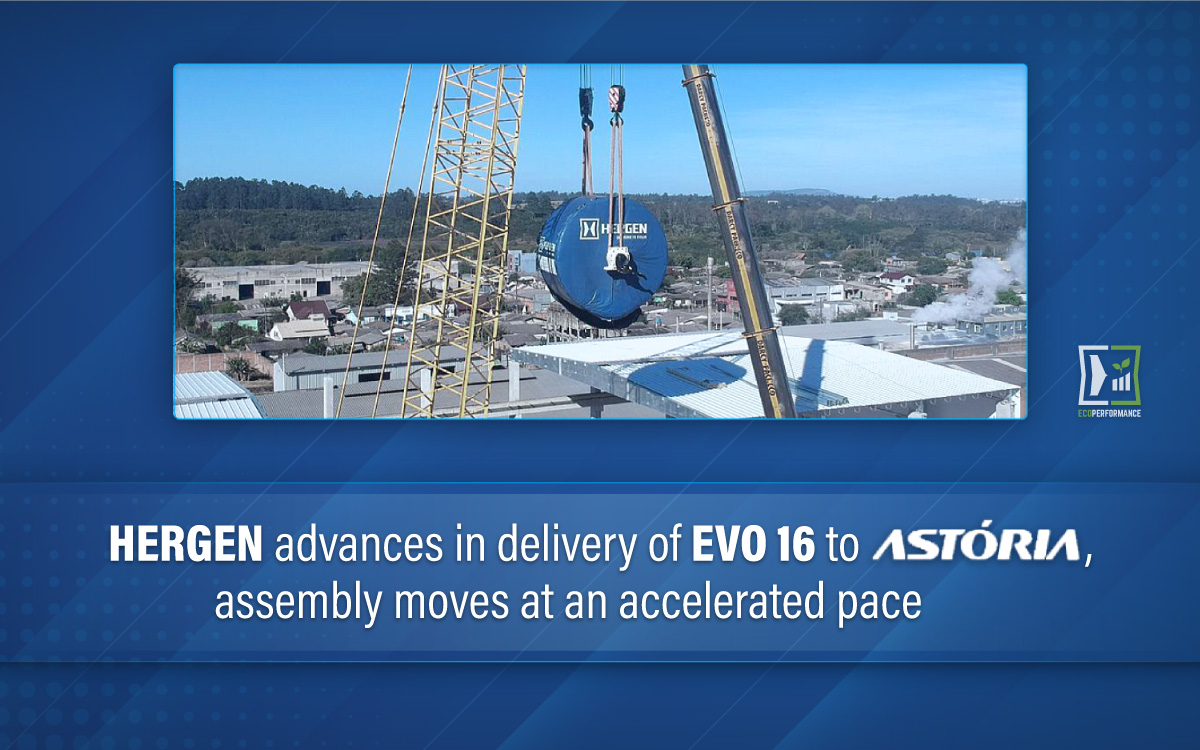

HERGEN is supplying ASTÓRIA with a new EVO 16 Tissue Machine, equipment developed to significantly expand the plant's production capacity and raise its standards of efficiency, quality, and operational reliability. Designed with state-of-the-art technology, the EVO 16 offers greater process stability, better energy performance, and high performance in paper sheet formation.

The project is in its final manufacturing phase, and a large part of the components have already been delivered, including the Smart Yankee Dryer, one of the main milestones of the supply.

At ASTÓRIA's facilities in Gravataí (state of Rio Grande do Sul - Brazil), the assembly of the new machine is progressing at an accelerated pace. With this strategic investment, the company strengthens its leading position in the market, consolidating itself as a reference in the production of high-quality tissue paper, with greater efficiency, stability, and competitiveness.

The new MP4 was developed to produce between 72 t/d and 92 t/d, with basis weights ranging from 12.5 g/m² to 28 g/m². With a design speed of 1,900 m/min and a sheet width of 2,780 mm at pope reel, the machine represents a leap in performance for ASTÓRIA's operation, combining productivity gains with higher quality in the final product.

Among the main highlights is the concept applied to the Crescent Former, essential for raising the quality standard and stability of the process. The Forming and Felt sections were designed with Cantilever structures, allowing a much faster and simpler fabric changes. In addition to significantly reducing downtime, this solution increases runnability and ensures greater operational availability, resulting in more productivity, better performance, and direct competitive gains for this customer.

Industry 4.0 and financial advantages

The EVO 16 project supplied to ASTÓRIA is fully aligned with Industry 4.0 criteria, incorporating advanced automation systems, intelligent sensors, continuous monitoring, and real-time data analysis. This level of digitalization ensures greater operational precision, complete traceability, and more assertive decisions based on process indicators. In addition to the technical benefits, the industry 4.0 features incorporated to the project, allows the client to access more competitive credit lines from development banks, which offer special conditions for investments in cutting-edge industrial technologies.

Furthermore, the classification as an Innovation 4.0 project is fully aligned with the guidelines of Industry 4.0, as it will significantly increase operational intelligence, control of critical variables, and the predictive capacity of production processes. This approach, in addition to modernizing ASTÓRIA's industrial management, also establishes a direct link with the strategic objectives of digitalization of Brazilian industry, advocated by the Federal Government and promoted through specific credit lines from its development institutions.

Smart Yankee Dryer technology: efficiency translated into results

The ASTÓRIA EVO 16 is equipped with the modern Smart Yankee Dryer, with a diameter of 4,880 mm, a national and international reference in heat transfer and high operational efficiency, significantly increasing the machine's productive performance.

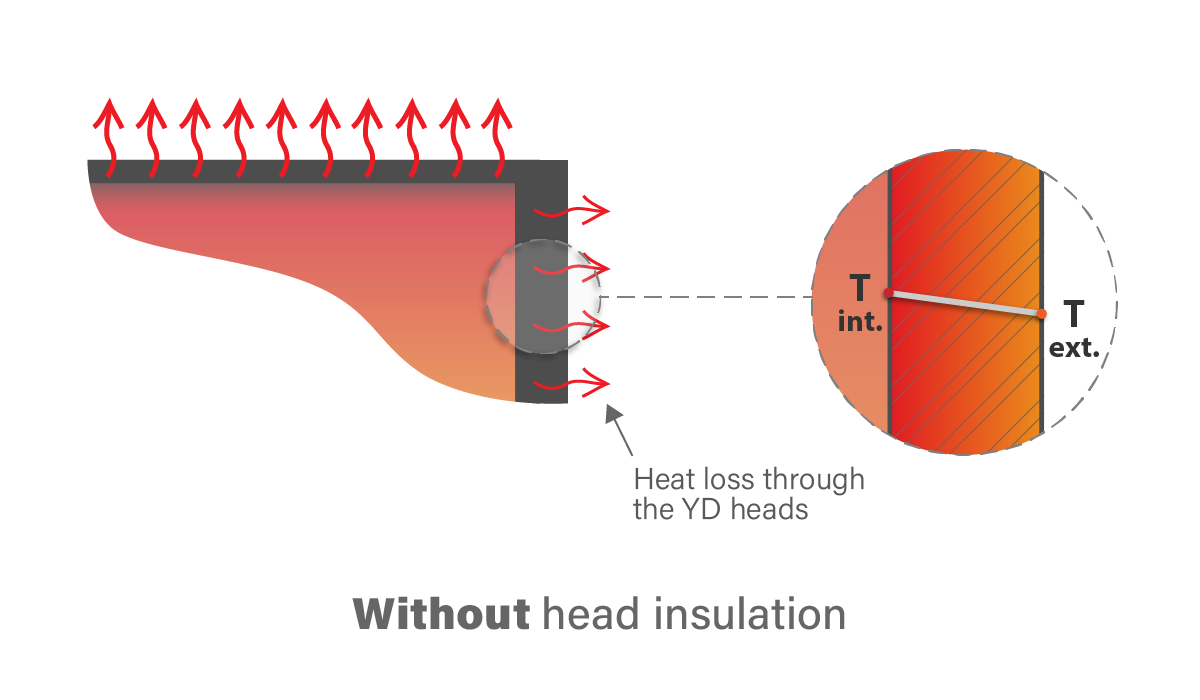

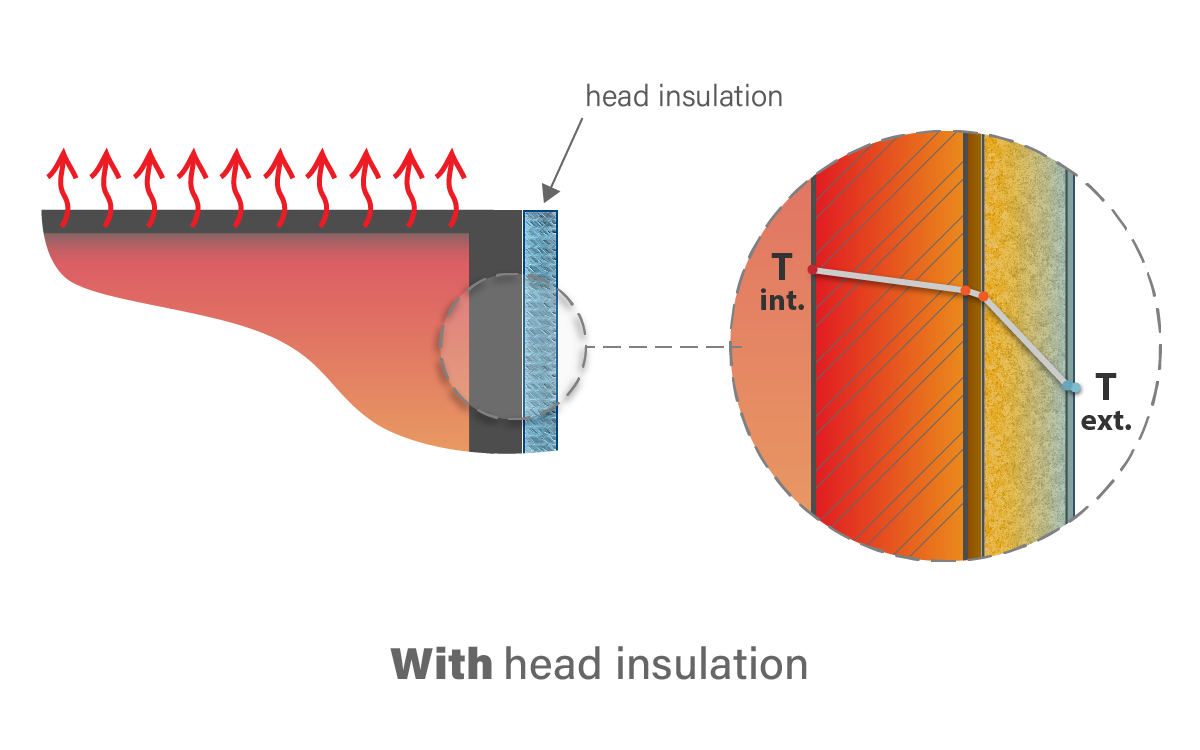

One of the great advantages of the Smart Yankee Dryer is the thermal insulation of its heads, which drastically reduces the heat losses. Field tests demonstrate that, while uninsulated heads reach external temperatures between 140°C and 150°C, in insulated heads these values drop to only 45°C to 55°C.

This efficiency gain can generate energy savings between 3% and 6%, depending on the cylinder diameter, directly reflecting in cost reduction or increased production. Furthermore, the insulation provides an essential benefit: greater operational safety. With much lower external temperatures, the risk of heat exposure for operators is significantly reduced.

Performance with responsibility: more production, less media consumption

Integrated into the ECOPerformance program, the new machine reinforces HERGEN's commitment to delivering solutions that combine technology, productivity, and sustainability. The project was developed to optimize energy and water consumption at all stages of the process, providing the customer with a machine capable of increasing productivity with superior efficiency, while reducing operating costs and minimizing environmental impacts.

HERGEN and ASTÓRIA

HERGEN thanks ASTÓRIA for its trust over the years and celebrates another chapter in this solid partnership. It is an honor to participate once again in its growth journey, offering not only machines, but technological solutions that drive results and build the future of the tissue industry in Brazil.