The future of tissue is sustainable! HERGEN presents trends and technologies at the ABTCP Workshop

November 27, 2025

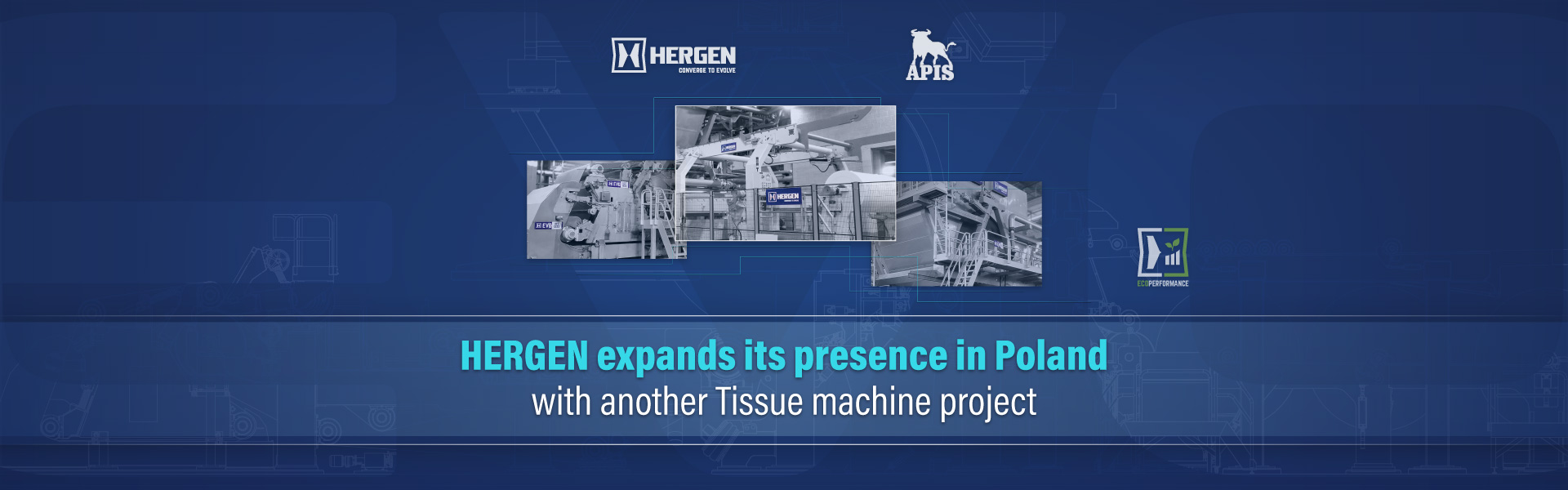

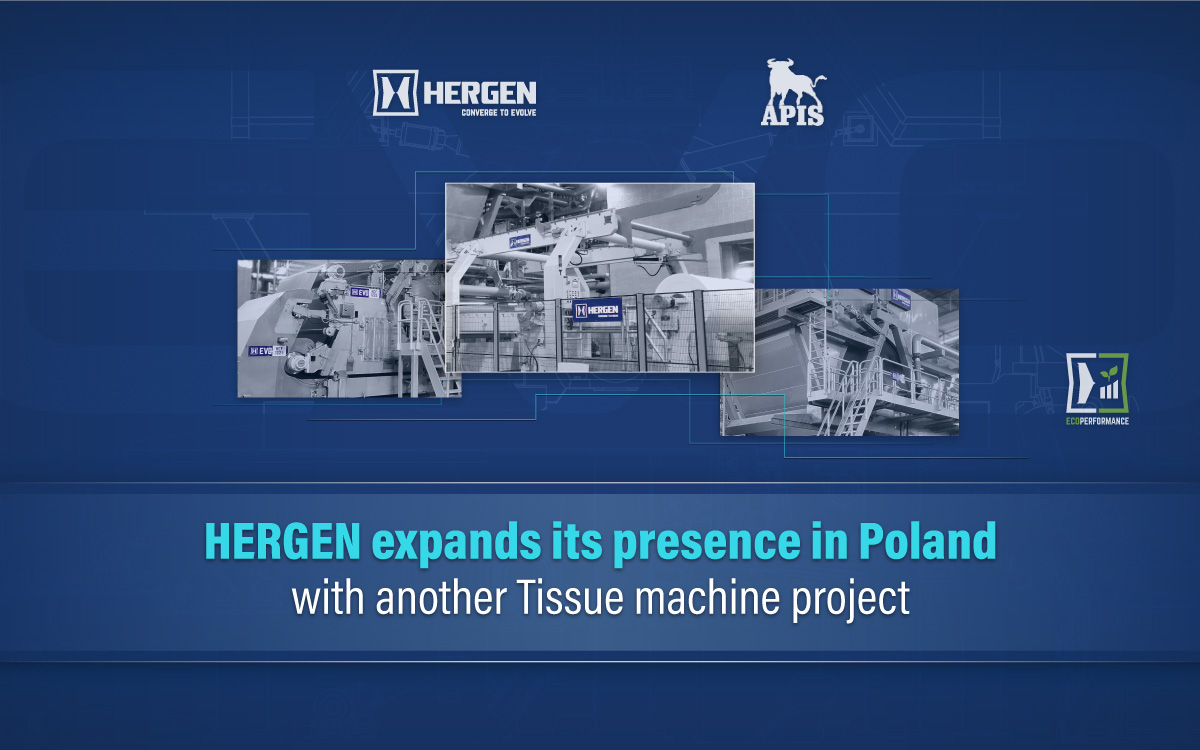

Over the past years, HERGEN has strengthened its presence in the Eastern European tissue market by delivering complete, high-performance solutions. We are currently manufacturing two new tissue machines, both destined for Poland. One of them will be installed at APIS, located in the city of Chodecz.

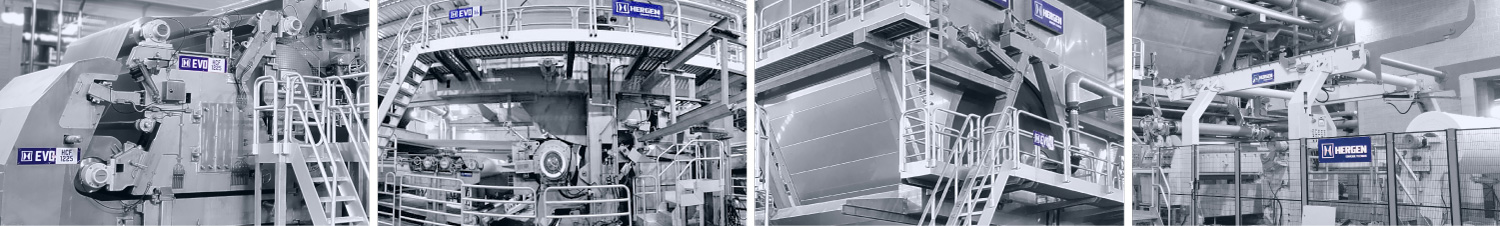

HERGEN Tissue Machines – illustrative images

Project overview

The new machine – MP2, model EVO 16 – was designed to expand APIS’s production capacity, with a focus on higher-basis-weight tissue grades such as toilet and towels produced with recycled fiber.

Designed to run at 1,900 m/min, the MP2 will produce papers starting at 16 g/m², with a 2,800 mm sheet width at the Rewinder.

The project also includes two presses equipped with a hydraulic loading system, ensuring efficient water removal, stable operation, improved paper quality, and lower energy consumption.

Productivity with responsibility

Aligned with the HERGEN ECOPerformance program, the new machine brings together productivity, efficiency, and sustainability.

The project emphasizes the use of recycled pulp and recovered paper, contributing to reduced environmental impact and optimized resource utilization.

The result is an operation that delivers more paper with lower consumption, reinforcing HERGEN’s commitment to high-performance technologies combined with social and environmental responsibility.

HERGEN and APIS

HERGEN extends its gratitude to APIS for the trust placed in our products and services and congratulates the company on this significant investment.

It is an honor for us to take part in this important milestone in APIS’s journey, contributing to its growth and competitiveness in the tissue market.