HERGEN promotes a Workshop in partnership with SENAI in the city of Videira

June 4, 2025

HERGEN to supply a new iNOVAFLOW Headbox to CAPRIMA

June 30, 2025

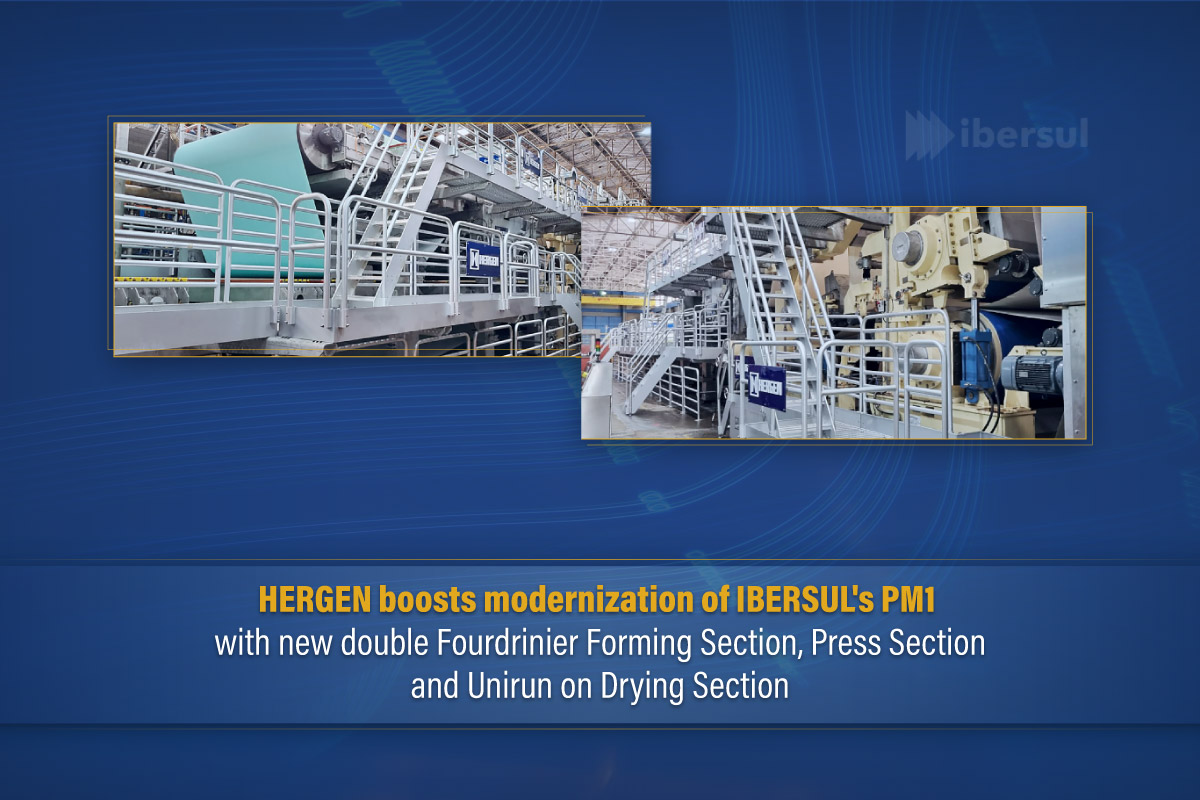

On June 3rd, HERGEN celebrated the successful start-up of another important supply: the new Forming, Press and Unirun sections of IBERSUL's PM1 are now in operation, marking a significant leap in the machine's performance. With the upgrade, the PM1 now runs on an average faster pace than before, immediately resulting in an increase in production.

Complete solutions for greater performance

HERGEN was responsible for supplying complete solutions for this step of the project, including two new Fourdriniers – Base and Top Layer – replacing the old Cylinder molds. The new Fourdrinier are entirely built in stainless steel, both Fourdriniers feature automated vacuum systems that guarantee greater efficiency and stability in sheet formation.

The scope of supply also included the complete Approach Flow system and the Couch-Pit, as well as the new Press Section equipped with a 1,210 mm diameter Jumbo Press and Sheet Stabilization System. The Drying Section first group received three Drying Cylinders operating with the Unirun concept, adding even more efficiency to the production process.

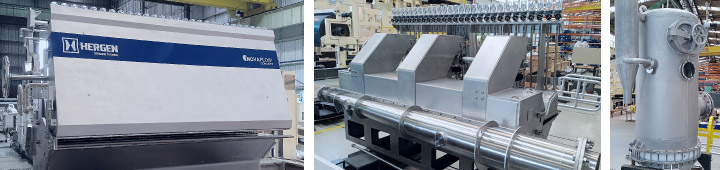

Technological highlight: Smart Flow Precision

One of the project's major distinguishing features are the two new generation Smart Flow Precision Headboxes, recently developed by HERGEN. Built entirely in stainless steel, this new line stands out for its mechanical robustness and superior geometric precision, guaranteeing operational stability even under high demanding conditions.

Ibersul Headboxes being assembled at HERGEN

Trusted Partnership

This supply is part of IBERSUL's PM1 revitalization project, which, when completed, will increase the unit's production capacity to about 8,000 tons per month. For HERGEN, it is an honor to be a technological partner in such a bold project. We reaffirm our trust in IBERSUL and together we celebrate another important milestone in the company's success story.

"The synergy between our teams enabled the entire project to be completed within eighteen months. Since start-up, the machine has produced excellent quality paper and a higher production volume than planned. We are satisfied with the results and are confident about the next steps of the machine modernization.”

Engineer Benedito Maciel Arantes Júnior – Director