HERGEN shares ESG strategies at the Unraveling Operational Efficiency Seminar

July 10, 2025

HERGEN Delivers Seven New-Generation SMART FLOW Precision Headboxes

August 14, 2025

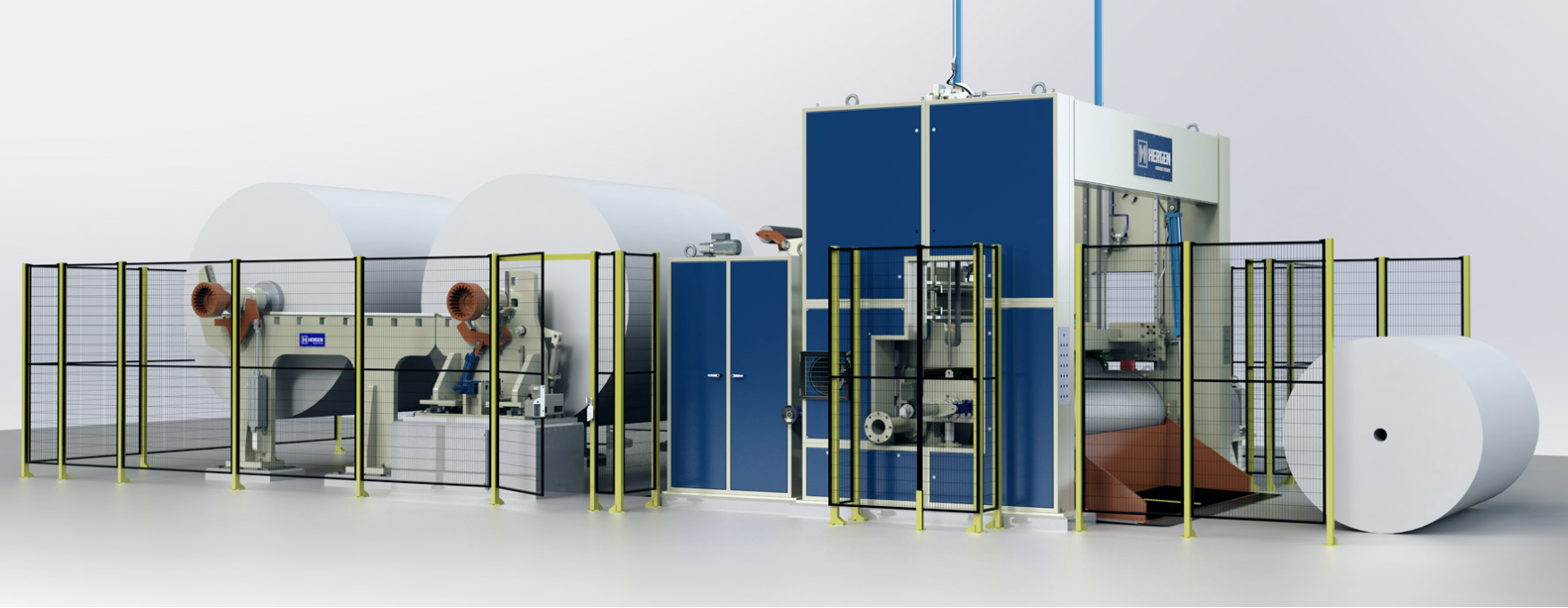

In just six months, HERGEN has once again proved why it is a benchmark in technology for the paper industry: four Excel line Winding Machines were delivered in the first half of this year.

The efficiency and fast delivery are impressive, but what really makes the difference is what lies behind this: quality, robustness, agility, and commitment to our customers' performance.

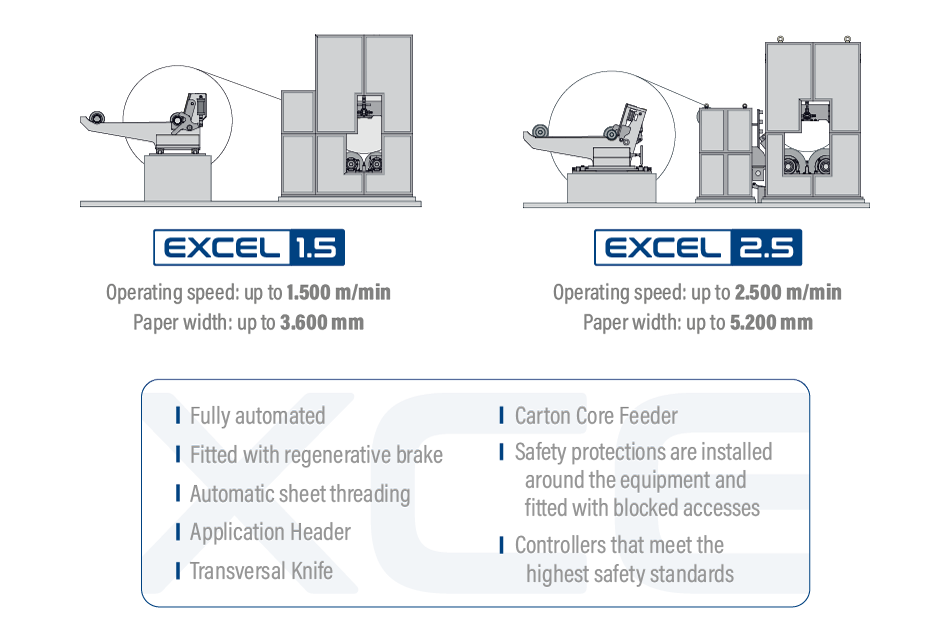

With cutting-edge engineering and a high automation level, Excel Winders are synonymous of efficiency. They feature high speed operation, deliver precise paper cut, ensure intelligent reuse of jumbo rolls, and optimize the entire paper conversion process.

Each project is unique. And HERGEN responds with flexibility and tailor-made solutions, always maintaining the standard that makes the brand one of the most respected in Brazil and abroad.

Highlights of the machines delivered — some of them are already in operation:

Engineering excellence: The machines delivered operate in different configurations, with working speeds of up to 2.600 m/min and multi-knife slitting systems, ensuring versatility in conversion processes.

Technology applied to efficiency: The Excel line of Winding Machines features automatic sheet feeding, unwinding station with regenerative electrical motor, and optimized tension control, reducing energy consumption and increasing operational safety.

Fast delivery without compromising quality: The feat of performing four deliveries in just six months reinforces HERGEN's production structure and commitment to deadlines and customer satisfaction.

Learn a little more about each supply:

Customer: Sylvamo

Model supplied: Excel 2.5

Operating speed: up to 1,600 m/min

Paper grade: writing & printing

Maximum paper width: 3,430 mm

Jumbo roll diameter: 2,010 mm

Wounded roll diameter: 1,500 mm

Hydraulic nip control

Regenerative drive system

Customer: Santa Maria

Model supplied: Excel 1.5

Operating speed: up to 1,000 m/min

Paper grade: special coated paper

Maximum paper width: 2,500 mm

Jumbo roll diameter: 1,500 mm

Wounded roll diameter: 1,500 mm

Hydraulic nip control

Regenerative drive system

Customer: Panasa (Ecuador)

Model supplied: Excel 1.5

Operating speed: up to 1,600 m/min

Paper grade: fluting and test liner

Maximum paper width: 2,400 mm

Jumbo roll diameter: 2,200 mm

Wounded roll diameter: 1,500 mm

Hydraulic nip control

Customer: Adami

Model supplied: Excel 2.5

Operating speed: up to 2,500 m/min

Paper grade: Fluting and test liner

Maximum paper width: 2,560 mm

Jumbo roll diameter: 2,650 mm

Wounded roll diameter: 1,500 mm

Hydraulic nip control

Regenerative drive system

Commitment to safety and sustainability

HERGEN maintains an ongoing commitment to operator safety and sustainability in the sector. The Excel line of Winders is designed with advanced safety features, such as access blocking systems during operation and controllers that meet the most strict international safety standards. In addition, they feature technologies that optimize energy consumption and reduce waste, contributing to a more efficient and environmentally responsible operation.

The achievement of this series of deliveries is yet another example of HERGEN's purpose: to offer innovative and sustainable solutions that exceed expectations in performance and quality in paper manufacturing.

Do you want to know how the Excel Winder can boost your production performance?

Talk to our specialist and find the ideal solution for your production.

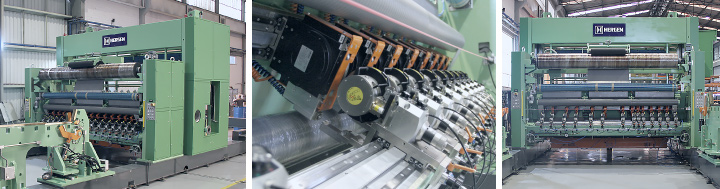

Proven quality