HERGEN delivers four Winding machines in the first half of 2025

August 7, 2025

HERGEN honored on ACIRS’s 80th anniversary with acknowledgment of Mr. Germano Purnhagen’s legacy

August 15, 2025

Greater strength, precision, and sustainability in paper production

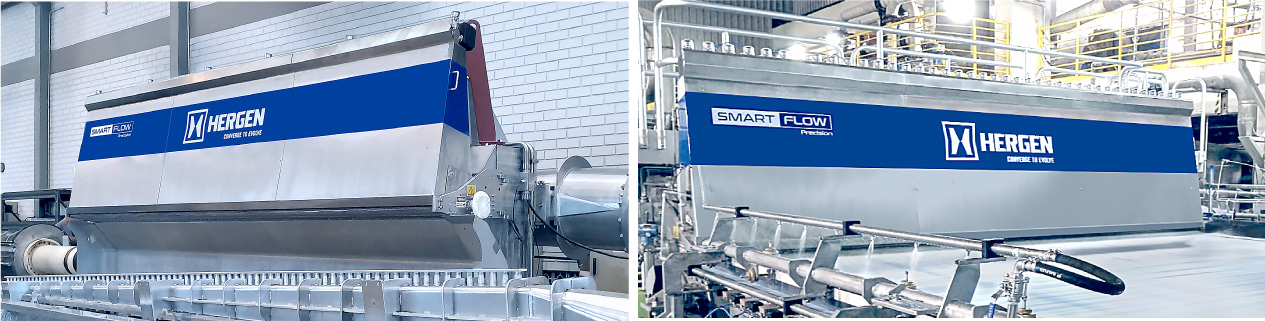

HERGEN has embarked on a new phase in providing technology to the paper industry with the delivery of seven new-generation SMART FLOW Precision Headboxes. Developed after the successful iNOVAFLOW line, the new generation combines high structural strength, superior geometric precision, and advanced basis weight profile control.

In one this installations, the SMART FLOW Precision was installed on a wide paper machine with an automatic dilution system, auto profiling system and fiber orientation control (Edge Control). The system achieved excellent operational performance from start-up, along with excellent stability and profile uniformity, validating the unique features of the new generation Headbox.

SMART FLOW Precision Headbox

Innovation and Technology at the Service of Quality

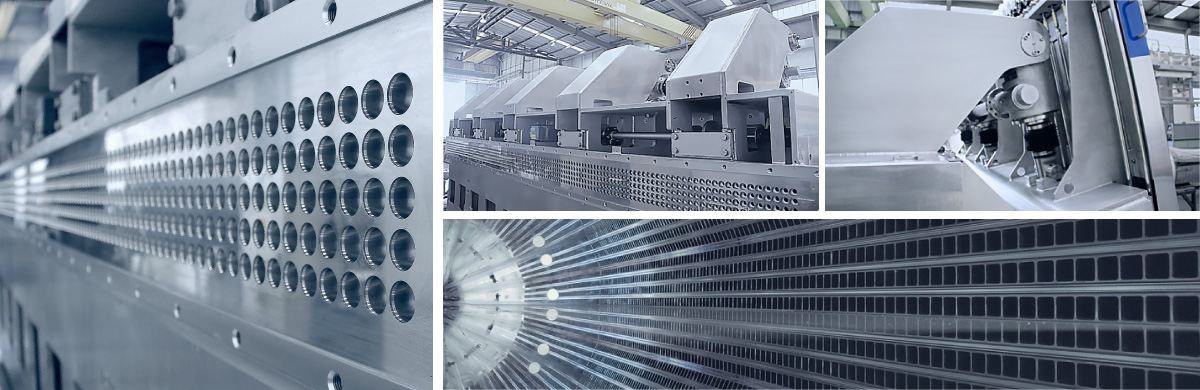

Designed with a 100% stainless steel structure, the SMART FLOW Precision ensures resistance under high working pressure and jet stability even under critical operating conditions. The new linear displacement system of the apron lip provides more precise adjustments of the paper cross machine profile, with less mechanical stress and greater reliability. Optionally, the Headbox apron lib can be manufactured in titanium, which significantly increases the durability and malleability of the part, even when using more abrasive raw materials.

Another highlight is HERGEN's exclusive QCS (Quality Control System) for cross machine basis weight and moisture control. The solution combines multiple types of actuators, integrating the apron lip's micro-adjustments with the dilution system in a coordinated and automated manner. This allows simultaneous control of dry and total basis weight, ensuring superior sheet quality and greater stability in the production process.

Performance that drives Sustainability

The new line is part of HERGEN's EcoPerformance program, bringing together solutions that optimize the use of supplies and reduce waste. SMART FLOW Precision allows for:

Reduced consumption of fibers, additives, and water

Greater stability of CD and MD profiles

Reduced necessity for manual intervention

Cleaner operation with less environmental impact

"With SMART FLOW Precision, we deliver a solution to the market that not only improves the machine's technical performance but also actively contributes to more efficient and sustainable production," emphasizes HERGEN's engineering team.

Versatile and Custom Design

The new Box can be configured to meet each customer's specific requirements. Supply options include:

• Side or radial pulsation attenuator systems

• Manual, automatic, or dilution-based BW profile adjustments

• Titanium apron lip (optional)

• Side bleed or Edge Control

— Ready for the challenges of the future —

SMART FLOW Precision arrives on the market as a reliable, high-performance solution, reaffirming HERGEN as a strategic partner in the paper industry.

HERGEN has been developing cutting-edge technology for the paper industry for 50 years.