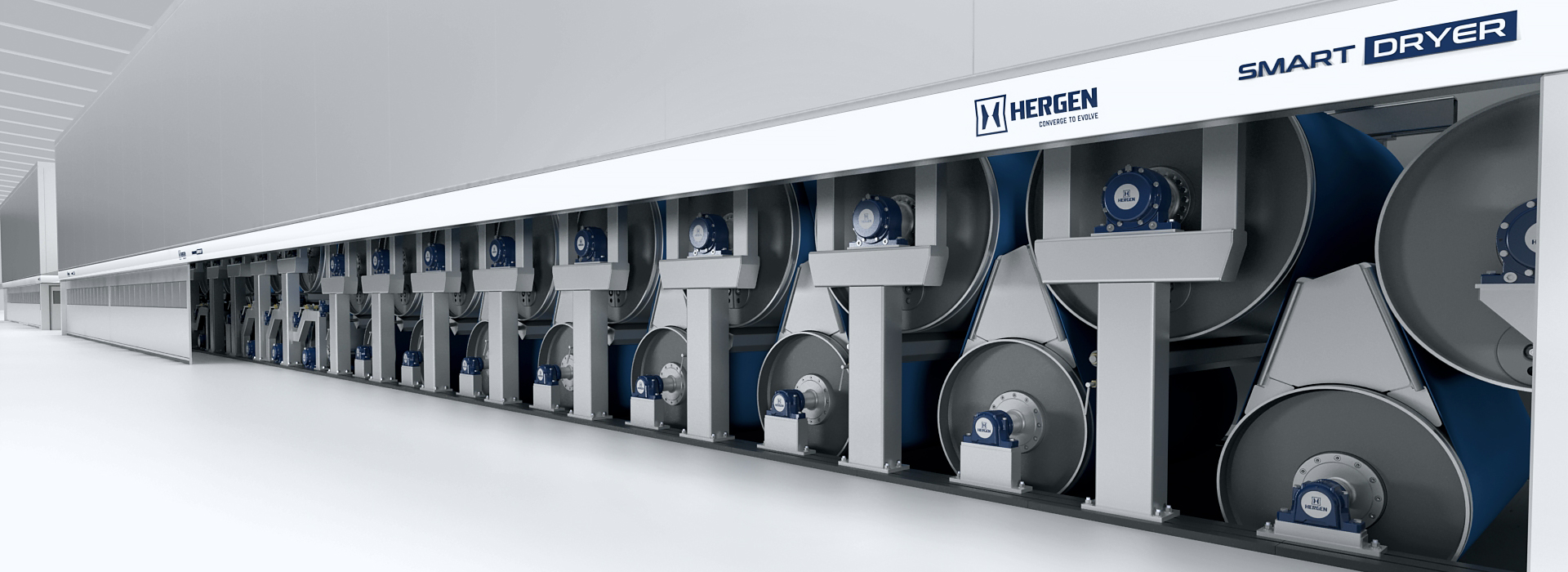

Hoods

HERGEN Hoods stand out for their excellent finishing standard and have been carefully designed to offer maximum efficiency, safety and practicality in both installation and maintenance. They are made of resistant, lightweight and non-flammable thermal insulation panels. The heat transmission coefficient of each panel is 0.44 W/m².k, surpassing traditional models available on the market.

The efficiency of HERGEN’s Hoods contributes significantly to preserving the heat produced in the Drying Section, resulting in energy savings. These savings not only bring economic benefits but also contribute to environmental sustainability. The reduction in steam consumption means a reduction in the demand for fossil fuels used to generate steam, which in turn results in a reduction in greenhouse gas emissions, minimizing environmental impact.

Another great advantage of HERGEN’s Hoods is the modularity of their panels, both side panels and roof panels, which are removable, considerably facilitating maintenance and access for any adjustment. This modularity allows quick and effective adaptations, as well as ensuring greater flexibility during operation.

In addition, the panels are prefabricated at HERGEN, which offers several benefits such as: a significant reduction in the amount of labor required for assembly, less downtime and, consequently, faster installation and quicker return of production. Prefabrication also ensures stricter quality control, resulting in a final product with greater reliability and durability.

Prefabricated panels at HERGEN

Supply

Designed according to each application – Open Canopy Hood or Closed Hood.

Complete Hoods with ductwork and fans for new machines or small upgrades for existing Hoods.

Benefits

Increases production.

Energy savings.

Paper course is protected against dripping due low external temperatures.