Hergen will provide a full Tissue Machine to FILAR, in Poland

Penha’s PM1 Modernization

May 22, 2019

START-UP of the SMART SIZER Starch Applicator

August 12, 2019Filar, PM1

Sadlno, Poland

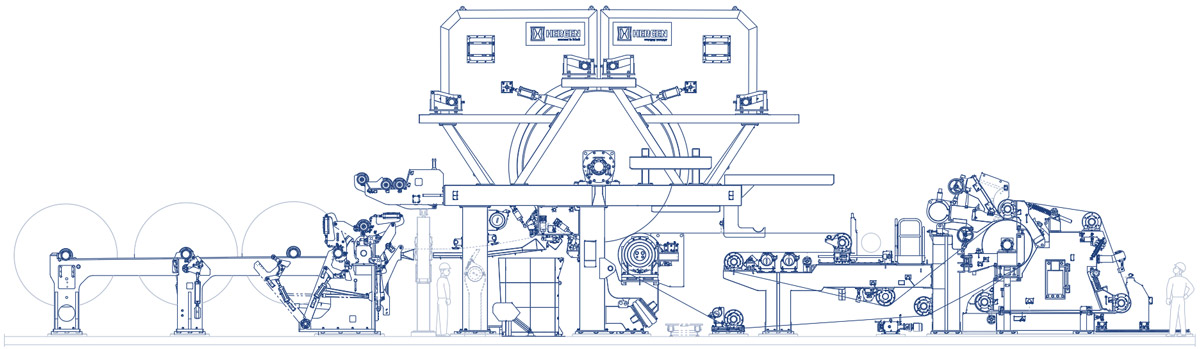

Filar Fijalkowscy Spolka Jawna, a company located in Sadlno, Gmina Wierzbinek region of Poland, has decided to enter the high quality Tissue paper market and is thus making a major investment in its facilities, including a complete new Tissue Machine supplied by Hergen. Start-up is scheduled for later this year.

The machine supplied will be an EVO 12 model, with Crescent Former HCF 1225, Suction Press with a diameter of 1,050 mm and Steel Yankee Dryer with a diameter of 3,660 mm.

Designed to work at 1700 m/min, the machine will produce 70 t/d of double-sheet paper (15 g/m2) and up to 100 t/d of other paper.

The project has two pulp lines (long fiber and short fiber), which allows them to work with products that can present excellent characteristics of softness and strength.

High performance with energy saving

Paper production consumes a lot of energy. In a Tissue paper machine, the drying process is responsible for about 70% of the machine's energy consumption. This means that a more efficient drying system results directly in significant energy savings.

Hergen Yankee Dryers are made of Steel. Due to the mechanical properties of this material, its thickness can be significantly less than the ones made of Cast Iron, increasing the heat transfer by up to 35%, resulting in lower energy consumption for the same production.

Hergen Quality

Over the years, Hergen has been supplying Tissue machines to various parts of the world, becoming one of the world's leading suppliers in this segment of the paper industry.

The success of many projects certifies the quality achieved by Hergen, developed with dedication, seriousness, competence, attention to detail and respect for its customers.