Two SIZE PRESS START-UPS with SMART SIZER Starch Applicators

HERGEN wins the 2023 ABTCP Industry Highlight Award

October 24, 2023

HERGEN took part in 4 Exhibitions at the beginning of 2024

March 19, 2024Two simultaneous start-ups

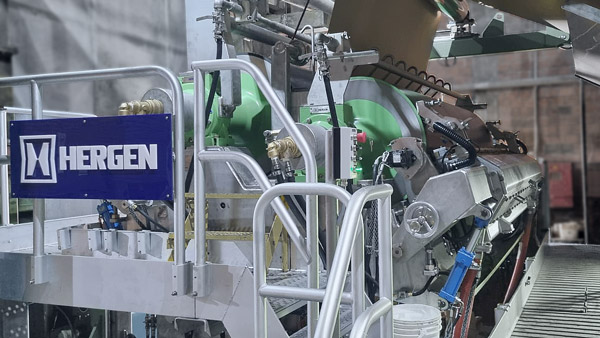

Last October, HERGEN has started up two Size Press equipped with Starch Application Headers. One of the projects was delivered to Brazil and the other one abroad.

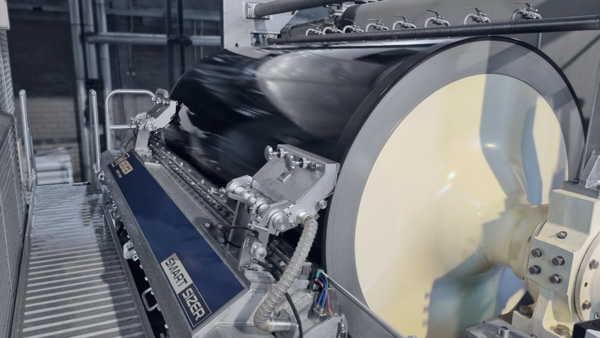

The Size Press is positioned between the Pre and Post Drying sections. Its main function is to carry out a surface treatment on the paper sheet, applying a solution to its surface.

The composition and purpose of the solution may vary depending on the specific requirements of each case. In both projects delivered by HERGEN, the solution applied consists of starch, with the aim of providing greater resistance to the paper sheet.

Both projects were designed with the mission of replacing the traditional pond system with HERGEN'S SMART SIZER Film Press system. Within this starch application concept, the heads precisely dose the desired amount, transferring it to the paper sheet. It is crucial to highlight that HERGEN'S SMART SIZER solution allows the application of different quantities and products on each side of the paper web.

Furthermore, both Starch Applicators incorporate stainless Steel Structures and larger diameter Applicator Rolls. We invite you to learn more details about these two innovative projects that have been started-up.

Some data about each project

| Brasil | Exterior | |

|---|---|---|

| Finished Paper Width | 2.600 mm | 2.650 mm |

| Machine Working Speed | 600 m/min. | 600 m/min. |

| Design Speed | 1.000 m/min. | 800 m/min. |

| Applicator Rolls Diameter | 1.500 mm | 700 mm |

| Maximum Solid Content | 14% | 14% |

SMART SIZER Benefits

Fiber savings

Savings on drying energy by adding less water to the paper

Application with solid contents of up to 14% starch

Greater control over the amount of starch applied, providing an excellent surface finishing to the paper sheet

Totally independent application on each side of the paper web, allowing different applications

Applicable on medium and high speed machines

Complete Solutions from HERGEN/HORST SPRENGER

HERGEN always seeks to employ the best technologies in its solutions. The Dosing Bars and supports used on HERGEN'S SMART SIZER are manufactured by HORST SPRENGER, a German company, which has extensive experience in manufacturing, installation, and technical assistance in Applicators around the world.

HORST SPRENGER accompanied the entire SMART SIZER start-up, ensuring the correct installation and operation of the Dosing Bars, in addition to providing training to the machine operators regarding their best use and maintenance.

Metering Size for Starch Application

Film Press Concept

All restrictions related to the use of the regular puddle Size Press are eliminated

High efficiency and stability even at high speeds

Starch is applied by two independent fully automated metering heads resulting in an extremely simple operation

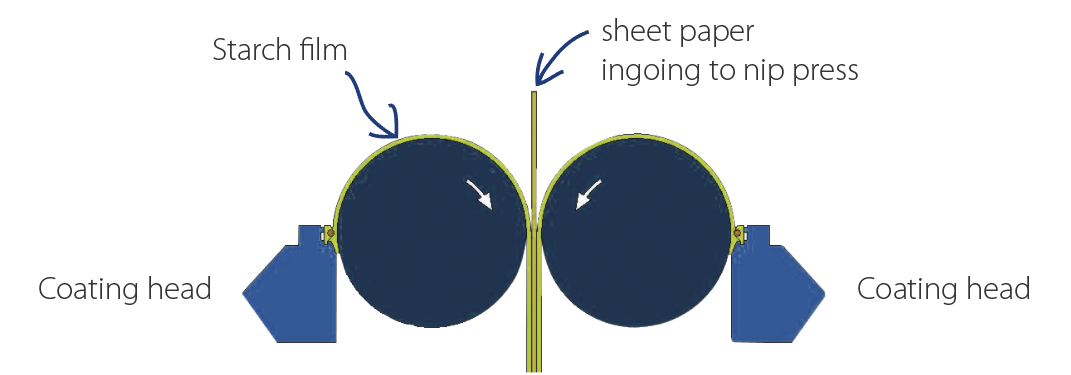

Functioning

Two Coating Heads are fed with a starch solution which remains in continuous circulation

A starch film is applied onto Nip Rolls by Metering Grooved Rods according to process requirements

In the Nip, the starch film applied onto Rolls Surface is transferred to the sheet paper