START-UP of the SMART SIZER Starch Applicator

Hergen will provide a full Tissue Machine to FILAR, in Poland

May 26, 2019

GREENPAPER – Install 10 new Steel Drying Cylinders 10 bar

August 26, 2019Start up: July 2019

Brasil

Project data

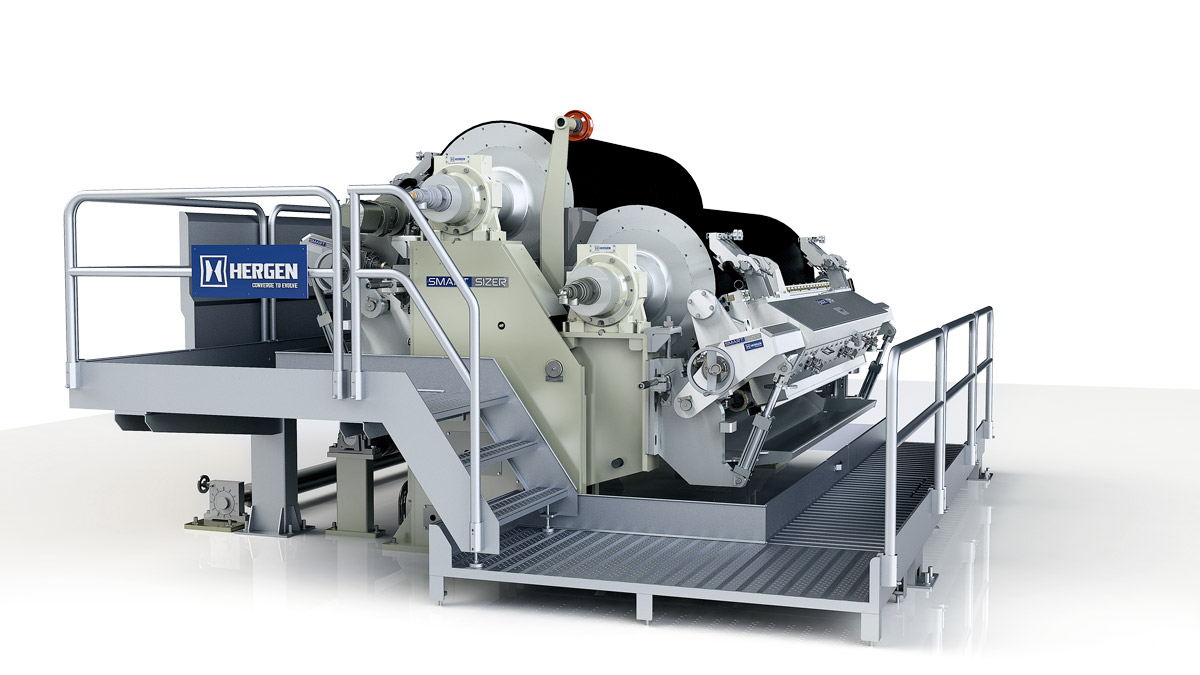

Finished paper width: 2500 mm

Machine speed: 800 m/min

Project speed: 1000 m/min

Applicator Roll diameter: 1000 mm

Applied product: corn starch

Maximum solids content: 14%

SMART SIZER benefits

Fiber saving

Drying energy savings since less water is applied to the paper

Starch film application with up to 14% solid content

Increase film starch amount control providing excellent sheet surface

Fully independent film application for each sheet paper side allowing different types of film application

For application in medium and high speed machines

Hergen/Horst Sprenger Partnership

The Dosing Bars and Cradles used in SMART SIZER are manufactured by Horst Sprenger, a German company, which has extensive experience in manufacturing, installing and giving technical assistance in starch applicators worldwide.

Horst Sprenger has monitored the entire start-up of the SMART SIZER, ensuring the correct installation and operation of the Dosing Bars, as well as training the machine operators on their use and maintenance.

FilmPress concept

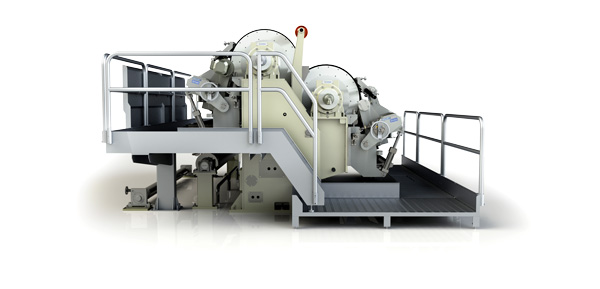

All restrictions when using a normal Size Press with puddle are eliminated

High efficiency and stability even at high speeds

Starch is applied by two independent fully automated metering heads resulting in an extremely simple operation

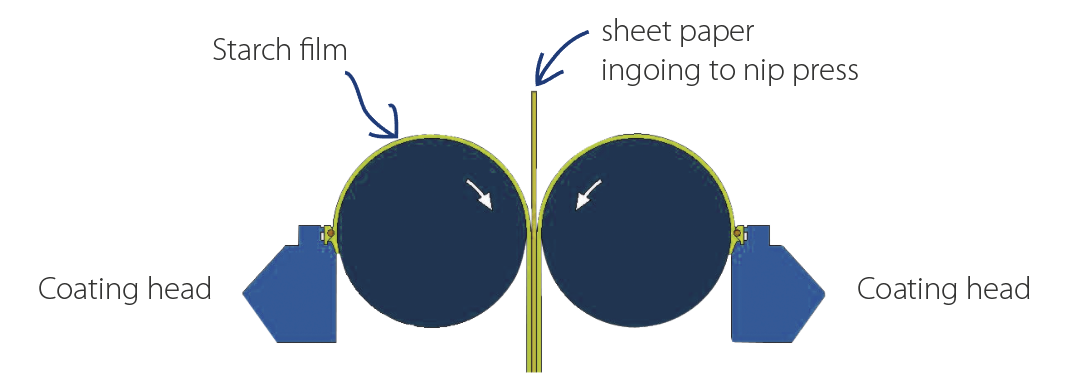

Functioning

Two coating heads are fed with starch solution which remains in continuous circulation

Starch film is applied onto nip rolls by metering grooved rods according to process requirements

In the nip, the starch film applied onto rolls surface is transferred to the sheet paper