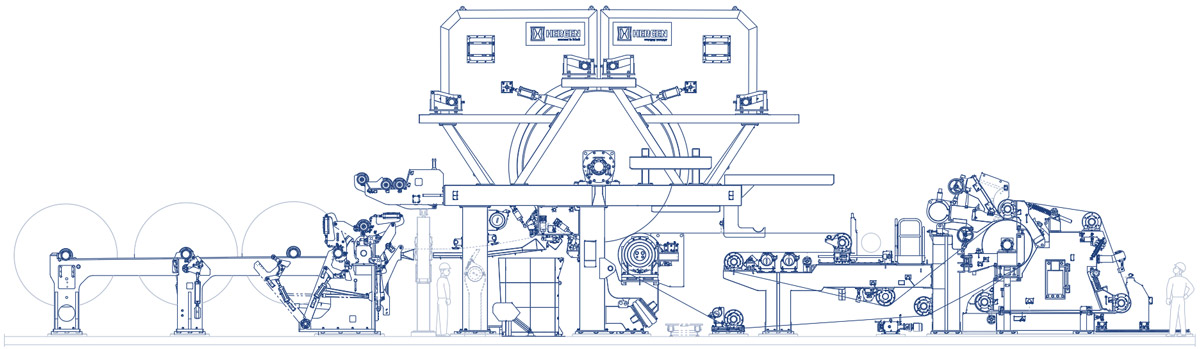

HERGEN Tissue Machine being assembled in Poland

Talk Tissue with IPEL after MP5 start-up

December 8, 2019

HERGEN modernizes TRÓPICOS’ TM3

December 18, 2019Filar, TM1

Chodecz, Poland

The works at Filar, in Poland, are in full swing. Assembly of the Tissue Machine manufactured by Hergen is well on its way and start-up is scheduled for the first half of next year

The supplied machine is the EVO 12 model, with HCF 1225 Crescent Former, Suction Press with 1050 mm diameter and 3660-mm Yankee Cylinder made of steel

Designed to work at 1700 m/min, the machine will product 70 t/d of two-ply paper (15 g/m2) and up to 100 t/d of other types of paper

The project has two lines of pulp (hardwood and softwood), which allows for working with products that present excellent softness and resistance characteristics

High performance with energy savings

Paper production consumes a huge amount of energy. In a Tissue paper machine, the drying process accounts for about 70% of the machine’s energy consumption. This means that more efficient drying leads directly to significant energy savings

Hergen’s Yankee Cylinders are made of Steel. Due to the mechanical properties of this material, it can be significantly thinner than Cast Iron, increasing heat transfer by up to 35%, resulting in lower energy consumption for the same production