IPEL achieves exceptional performance with its new TM5

OL PAPÉIS’ TM3 starts being delivered

July 15, 2020

WILLIAM SANTOS participates in the Tissue Online Panel

August 6, 2020

Indaial, SC, Brazil

A great success!

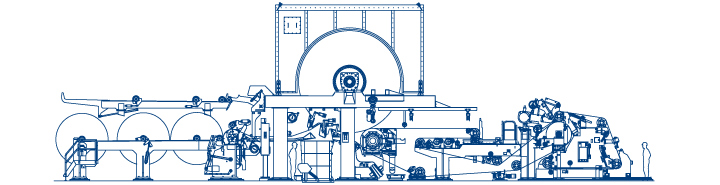

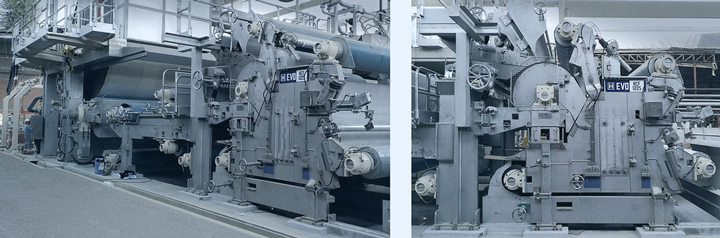

IPEL's new Tissue Machine – TM5 – has been running since September last year. The great advantage of the project is that, in this first stage, the machine – model EVO 16 ECO, supplied by Hergen – works without a Hood, relying only on the Yankee Cylinder for sheet drying.

A Fan Guard was installed in place of the Hood, which simply aims to extract the steam generated by drying the paper. The Hood uses only two small fans with extremely low energy consumption. This setup allows the extraction of maximum machine performance.

The results in this first stage have been excellent. Initial production estimates were reached and even exceeded. On July 16, the customer recorded a production of 71.1 t/d. .

First stage: without Hood, only extraction Fan Guard

The Yankee Cylinder's role

The TM5 excellent performance is due to the extreme drying capacity of the Smart Yankee Dryer. Built in steel and with a grooved internal surface, they allow for greater heat exchange and, consequently, greater drying efficiency.

Hergen Cylinders have stood out in the market for this high drying efficiency. Their excellent heat transfer provides a higher rate of paper evaporation, resulting in increased production.

This was exactly the case for Ipel. The Yankee Cylinder efficiency, alone, enabled great results, extracting the maximum machine performance in this initial setup.

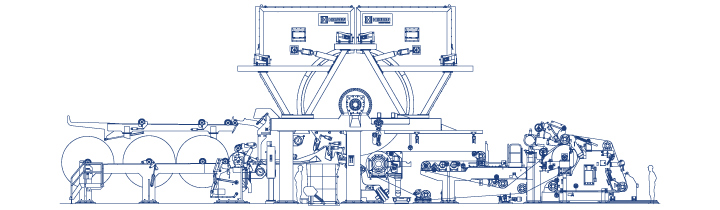

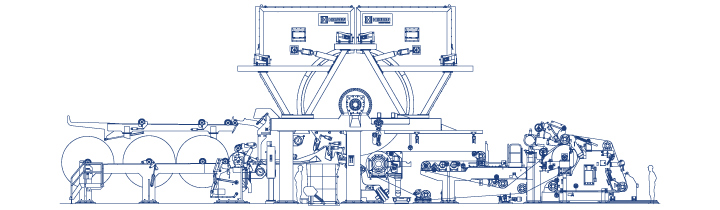

Second stage

The expressive numbers registered so far point to a very promising second stage, following the Hood installation.

In this first stage (without the Hood), the machine reached a production capacity of 70 t/d for double sheet paper (14.5 g/m2), running at 1,500 m/min.

In the second stage, with the Hood installation, the machine will be able to exceed 85 t/d for double sheet paper, running at 1,800 m/min.

Second stage: with Hood

Teamwork

Another aspect that needs to be highlighted is that the great success of this project would not be possible without the excellent partnership of IPEL. Their highly trained and motivated team made a difference throughout the process.

Congratulations to the entire HERGEN/IPEL team!

Some key information about the project

INOVAFLOW Hydraulic Headbox

Crescent Former HCF 1225

Suction Press Ø 1,200 mm

Yankee Cylinder Ø 4,880 mm, built in steel and with a grooved internal surface

Hydraulic roller with extended track, Roll Core feeding and Empty Roll Core collector

TM5 being installed in 2019

The Hergen Commitment

Among Hergen's guidelines and values, the first one is: "Providing products with authentic quality".

Thus, it is always a great satisfaction for us to know that our customers' expectations have been met and even exceeded.

We work continuously and tirelessly so that, like IPEL, all our partners feel respected when working with us and have full confidence in our commitment to providing solutions with quality, seriousness, and efficiency.

HERGEN TISSUE MACHINE

High-performance Tissue Machines up to 2,200 m/min

Drying and pressing concepts that deliver excellent cost effectiveness per ton of paper produced.

Flexible designs that allow for gradual upgrades starting from a basic model.

Proven engineering experience, with customized solutions that allow achieving performance very quickly and safely.