HERGEN delivers Pulper Off Machine for waste recovery

Improved machine runnability and increased safety

June 28, 2021

AVELINO BRAGAGNOLO will install a new Rewinder at MP3

July 21, 2021Reducing waste

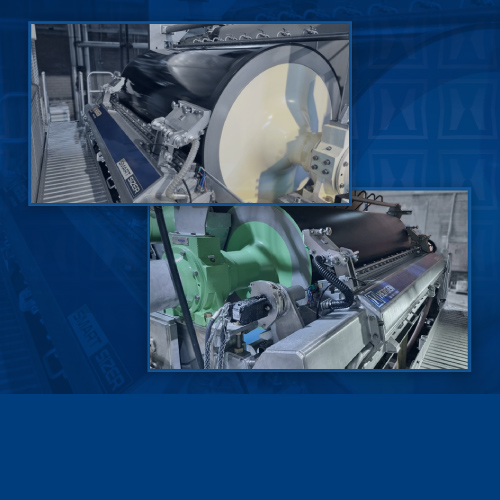

The installation of a Pulper Off machine, supplied by Hergen, was completed in the state of São Paulo. The purpose of this machine, installed separately from the existing equipment, is to reuse the waste left over at the end of the paper manufacturing process.

The Pulper transforms waste into reusable fiber which returns to the circuit, thus reducing process losses.

Rails for take-up rolls

The machine also has rails for take-up rolls. It is fitted with a motorized unwinding system with rotation control via pneumatic shoe brake.

This system allows to control the speed at which the paper falls on the Pulper.

Versatile design

Different types of scrap are accepted as input, including machine breakage blanket, rewinder trims or waste from the take-up roll.

Other design data:

Distance between rail centers = 5500 mm

Rotor diameter = 720 mm

Pulper tank capacity = 10 m3

Maximum breakdown load = 4.0 ton/h

Power output = 90 kW

Start up are scheduled for November.