More efficient and cost effective drying

Two more Drum Dryer Cylinders for IDAHO STEEL in the USA

August 16, 2021

Yankee Dryer delivered to DAMAPEL

September 17, 2021

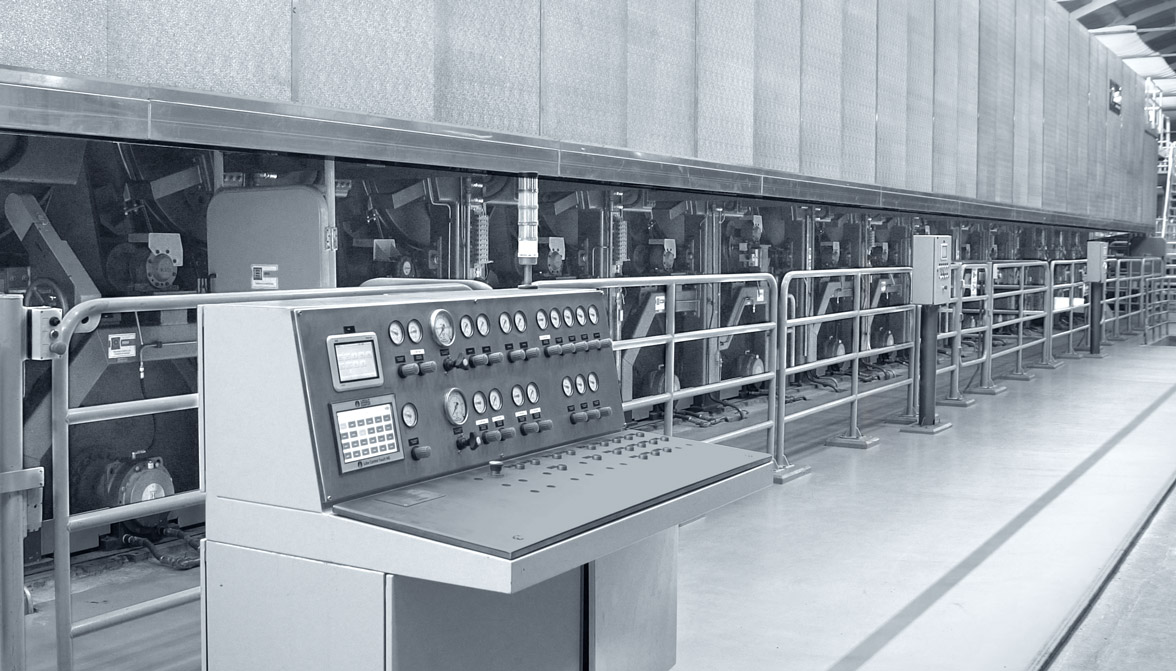

The drying efficiency increase is a quite important issue on paper industry, since that this part of the manufacturing process is the one that presents the highest costs.

The Smart Steel Dryer – fabricated by HERGEN – combine proven features that at same time improve efficiency and optimize the costs.

More efficiency

Drying Increase

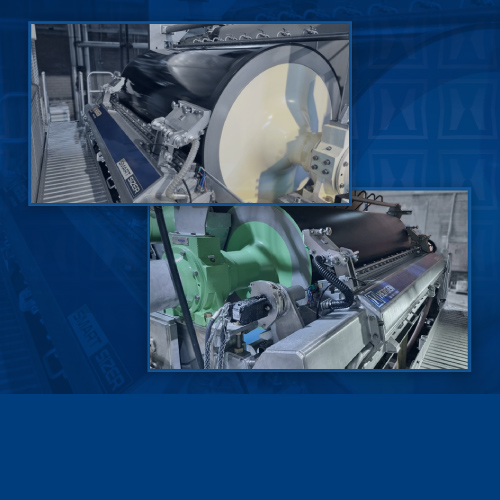

The Smart Steel Dryer are fabricated with a steel alloy that enables a thinner shell, which results on

a higher heat transfer rate to the paper web.

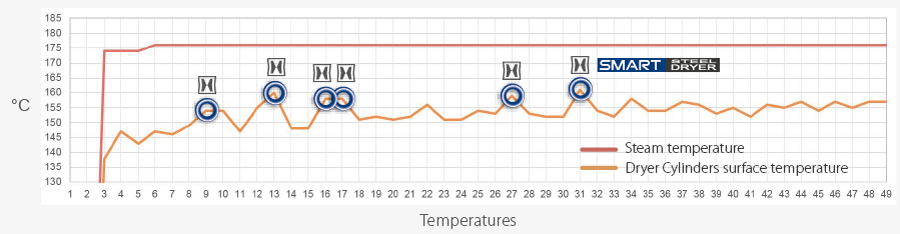

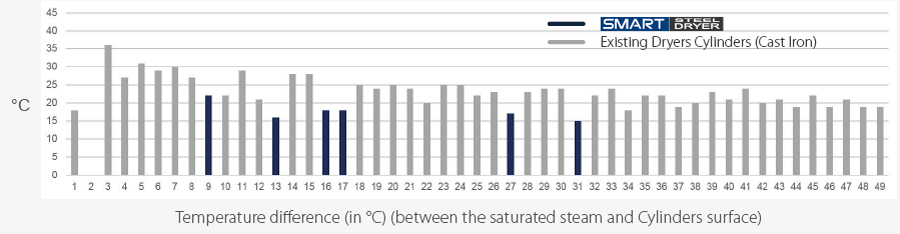

Real-life Case:

Six of the 49 existing cast iron dryers have been replaced by brand new Smart Steel Dryer

The Smart Steel Dryer features a smaller temperature difference between the saturated steam and cylinder surface when compared to conventional cast iron cylinders.

Excellent Temperature Profile

It features a more uniform temperature profile through the whole cylinder face length.

Safety Increase

ZERO risk of explosion due to carbon steel fabrication.

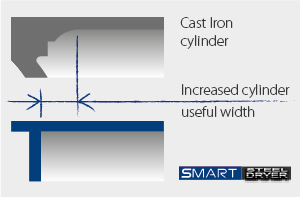

Working width increase

Due to the compact construction of the Smart Steel Dryer, it enables a wider working width, which my help solving wet edges problems.

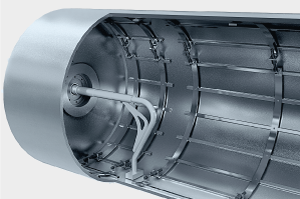

Turbulence Bars

Increases cylinder drying capacity.

Improves drying / moisture cross profile.

Outstanding savings

The higher efficiency of the Smart Steel Dryer enables a reduction of the number of dryers required on pre and post drying sections, reducing the initial operation cost.

The Smart Steel Dryer features a lighter construction when compared to the conventional cast iron ones, this fact reduces the energy cost required for PM drive.

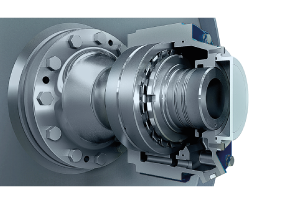

Flanged assembly of the Rotary Joints

This feature allows precise alignment between rotary joint and dryer journal,

which reduces the sealing wear.

Oil lubricated bearing housings

This feature increases the roller bearings lifespan and reduces the

maintenance requirements.

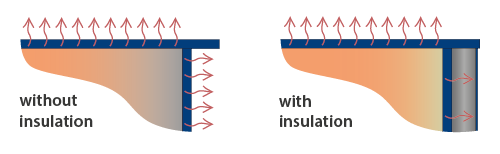

Head thermal insulation

The drying cylinders loses heat through their heads which means a continuous energy waste, with the thermal head insulation it is possible to minimize this effect which results on a considerable energy savings.

Reduced maintenance

The heads are welded to the dryer shell, this process eliminates any possibility of steam leakages through this joint.