GUAPI PAPÉIS boosts PM1 complete modernization

INPEL acquires NEW Tissue Machine

November 29, 2021

HERGEN receives Russian Certification for Pressure Vessels

February 14, 2022

Guapi Papéis - Eco Import

Guapimirim - RJ - Brazil

Another important step

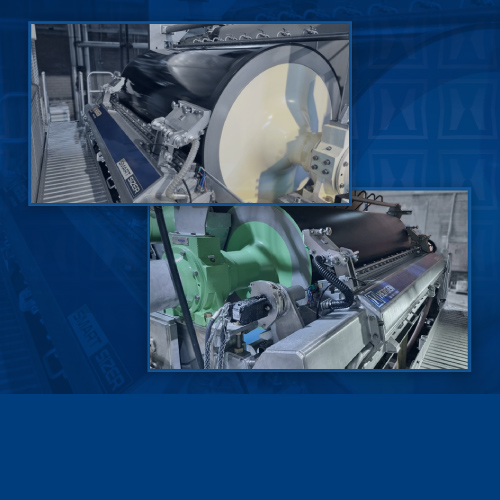

In order to continue the project to reactivate its PM1, GUAPI PAPÉIS has just purchased a new Fourdrinier.

The project – which will be supplied by HERGEN – includes all dewatering devices, vacuum header with the air/water separators set and control valves. The Fourdrinier frames will be prepared for the future installation of a top Fourdrinier and completely built in stainless steel, providing the machine with a longer lifespan.

The new hydraulic headbox – iNOVAFlow concept – will also be entirely built in stainless steel. The headbox feeding will be done with a radial distribution system (octopus type).

It is a virtually new machine

In 2021, GUAPI had already acquired a new press section, a new drying section and a new pope reel for its PM1, all equipment supplied by HERGEN.

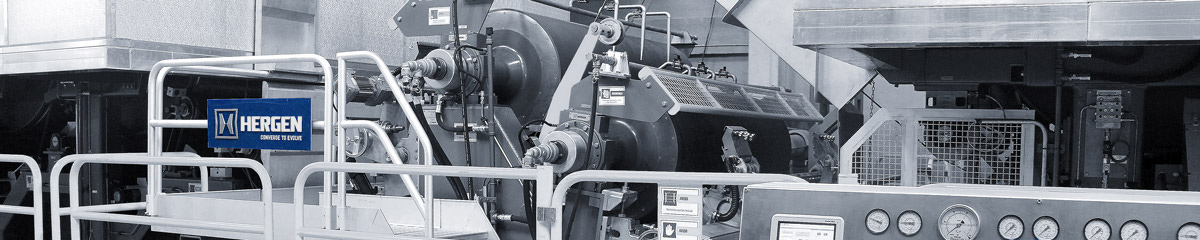

Now, with the acquisition of a new Fourdrinier, it can be said that the PM1 will be a new machine, designed for a future speed of 850 to 1,000 m/min.

HERGEN/GUAPI PAPÉIS

This new project is another big step in the close partnership between the two companies.

In 2019, HERGEN supplied the new MP2 for GUAPI, a machine that has broken straight production records.

For HERGEN it is a great satisfaction to work along with GUAPI in this long term and very successful partnership. We are honored to be part of this successful story.

GUAPI PM2 supplied by HERGEN in 2019

GUAPI PM2 supplied by HERGEN in 2019

GUAPI PM2 supplied by HERGEN in 2019

GUAPI PM2 supplied by HERGEN in 2019

HERGEN - Paper and Board Machines

Forming Sections

Complete sections with primary and secondary fourdriniers

Headboxes with pulsation attenuators

Frameworks are fully Stainless Steel cladding

Dryer Cylinders

Made of Steel (increased efficiency and reduced costs)

With ASME Certification

With Turbulence bars and thermal insulation

Metering Size for Starch Application

Fiber saving

Improvement in physical tests

Drying energy savings

Starch film application with up to 14% solid content

Rewinders

Fully automated, with regenerative brake, automatic sheet threading,

application Header, transversal knife, carton core feeder

Equipped with all necessary devices to ensure operator safety