HERGEN promotes Open House for its SHOE PRESS

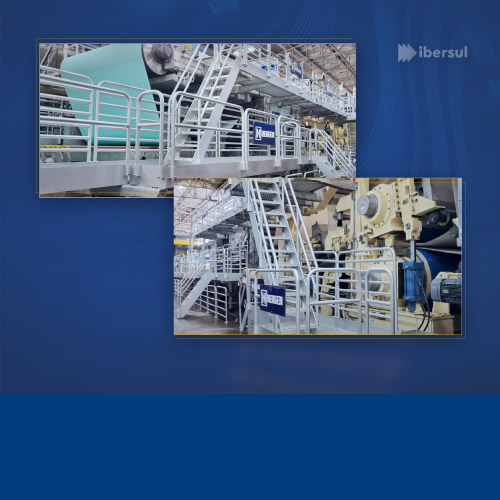

HERGEN Retrofits COBAP PM#1

August 26, 2022

PAPEL TANGARÁ starts up its new Tissue Machine

September 26, 2022

A great event

HERGEN will promote on from October 18th to 20th an Open House for the launching of its Shoe Press, at its headquarters in Rio do Sul - SC - Brasil.

The event's main objective is to present HERGEN's latest innovation and technological development: the SMART SHOE (Hergen's Shoe Press Concept).

The Shoe Press will have a special highlight in this event that will feature technical presentations with the equipment in operation. There will be assistance by the engineers responsible for the project, creating a unique opportunity for everyone who wants to know more details about this project.

The relevance of the event is even greater because it is a shoe press produced entirely in Brazil, with HERGEN being the only manufacturer of paper machinery with technical, manufacturing and technological capabilities for this feat throughout the whole Latin America.

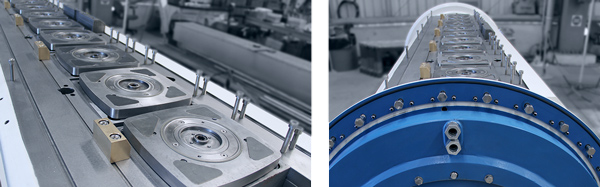

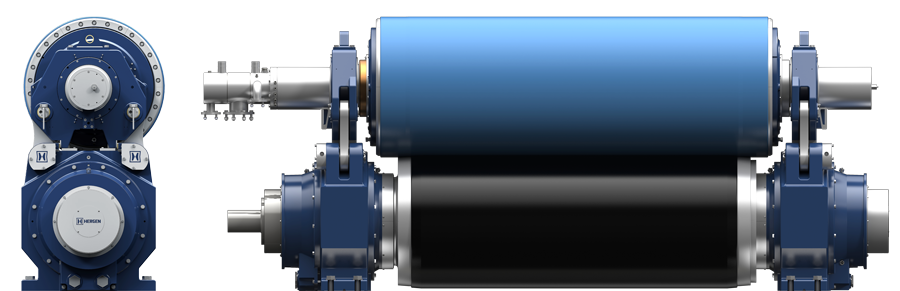

SMART SHOE during assembly at HERGEN’S workshop

You are our guest!

At the event, we will exhibit components and sections of a paper machine that are also worth mentioning, such as: Headbox, Size Press, Fourdrinier, Rewinder and Fabricated Drying Cylinders.

It will be a unique opportunity to discover products manufactured using the most recent concepts of innovation and designed focused in high-performance and energy-efficient projects. It will also be possible to visit HERGEN's high-tech facility, accompanied by our technical engineering staff.

Come and join the Open House and learn about our technological solutions in papermaking machinery.

It will be a great pleasure to have you here!

To schedule your visit, click here.

HERGEN Shoe Press, one step further

Throughout the years, the history of HERGEN has been built with hard work, the use of technological innovations and a focus on the customer.

The search for excellence and the involvement of all employees to build the best solution make this project very special for HERGEN and to the market.

The constant technological development is what allows HERGEN to be a reference and accredits it as the only shoe press manufacturer in whole Latin America.

During the research and development phase, the technical staff made their best efforts and focused on the creation of a press that delivers higher dry content and ensures maximum paper quality while keeping the volume and structure of the sheet.

The result was an innovative, robust and precise product, designed within the most modern engineering concepts for shoe presses in the world. In this project, HERGEN prioritized increasing performance, energy saving and minimizing the use of fiber.

It took a lot of research and development to make it possible the production of equipment with enormous operating precision and magnitude, which highlights the great challenge that this project presented. This achievement is another step forward and one of appreciation for its team of employees.

HERGEN SMART SHOE Features

Fully automated, making your operation simple and safe.

Counter Roll without compensation system, resulting in a more economical project and reducing the maintenance requirements.

Systems with minimal maintenance and low cost.

Compact design, featuring easy installation on existing machines.

| Technical Data | |

|---|---|

| Ø Shoe Roll | 1.262 mm |

| Ø Counter Roll | 1.200 mm |

| Nip width | 280 mm |

| Linear load | Designed up to 1.300 kN/m |

| Paper width | Designed up to 5.000 mm |

What are the advantages of the HERGEN's SMART SHOE?

With the growing demand in the packaging market, the increase in machine speed and the need to reduce paper manufacturing costs, it has become increasingly important to improve the sheet dewatering capacity.

The costs related to paper evaporation are very high, making it imperative to maximize the sheet dewatering capacity before drying section.

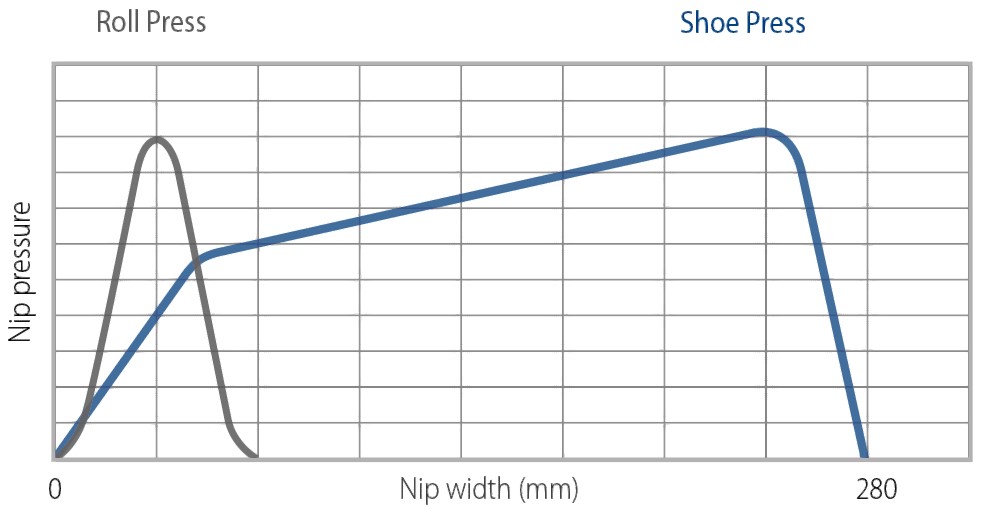

In the Shoe Press, the nip width is considerably wider compared to conventional presses. This increases the sheet dwell time in the nip region and, consequently, the Press Impulse. By increasing the Press Impulse, it is possible to increase the dry content of the sheet and reduce the thermal energy requirements. Finally, it is possible to gain performance with cost reduction.

Another important aspect is that, although the sheet stays a longer time in the nip region, the specific pressure on the paper is not greater than in Roll Presses. This allows to increase the dewatering more homogeneously, without damaging the sheet structure.

| Design Criteria | Press Roll | Shoe Press |

|---|---|---|

| Nip width (mm) | 40 - 70 | 250 - 280 |

| Working nip load (kN/m) | 150 - 450 | 1000 - 1300 |

| Press Impulse (psi.s) | 2 - 5 | 10 - 21 |

In this way, some of the Shoe Press benefits are:

Production increase

Higher drying content

Less thermal energy consumption

Improvement on paper sheet physical tests

Low maintenance

HERGEN modernizes

double width Shoe Press

Recently, HERGEN has been selected by a major paper manufacturer to modernize its Shoe Press.

This is a double width press (shoe length = 4,905 mm) that has been in operation for more than 20 years. It was necessary to perform a series of improvements, in order to eliminate some limitations and increase the mechanical precision and efficiency of the Press. Furthermore, the use of modern concepts used in the HERGEN design could optimize results and increase the belt lifespan.

Modern concepts applied

The Loading System has been completely replaced. The new system uses multiple cylindrical pistons arranged in two load lines. This concept, in addition to being more efficient, significantly simplifies maintenance. The design also guarantees the precise positioning/alignment of the Shoe, which is essential for the Press efficiency.

In the design of the new Shoe, special attention was paid to its cooling, with the aim of increasing the life of the belt, especially the grooved type. In addition to other improvements, the Shoe now has internal channels for cross-circulating cooling.

The bearing housings – in both the Shoe Roll and Counter Roll – have been completely replaced and now integrate devices that keep the two Rollers precisely aligned with each other.

Solutions for the paper industry