After modernization, IRANI’s MP2 breaks production record

INPEL STARTS UP its New TM#2

November 9, 2022

HERGEN presents three lectures at ACOTEPAC 2023

February 21, 2023

IRANI Papel e Embalagem

Vargem Bonita, SC, Brazil

Thanks to the excellent work of the IRANI/HERGEN team, the modernization of the MP2 was a great success!

The start-up took place on the 21st of October with the machine running well from the very first days.

Even with the numerous interventions carried out in all sections of the machine, just eight days after start-up, the machine broke its former production record.

October 21st – Start-up day

October 29th – Production record

All that what was done

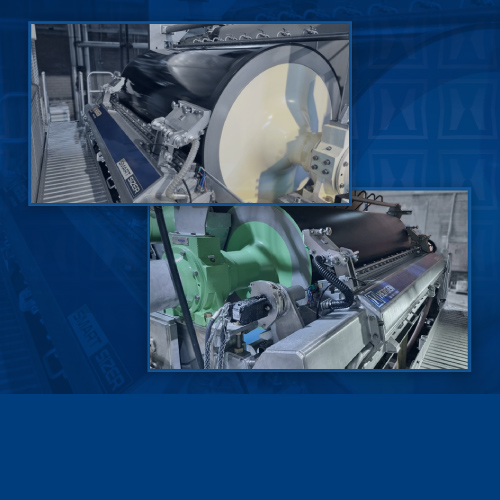

The modernization - carried out by HERGEN - completely replaced the Drying Section, including the MG Dryer.

The package also included a new Pope Reel, a new Lumpbreaker Roll and improvements to the Fourdrinier, Press Section and Rewinder.

Production Increase

All former cast iron Drying Cylinders have been replaced by larger diameter Steel Dryer Cylinders.

The larger drying area, combined with the greater heat transfer from the Smart Steel Dryer Cylinders produced by HERGEN, resulted on a higher production capacity.

Quality Improvement

The old Cast Iron MG Dryer was replaced by a Steel MG Dryer of 4,200 mm of diameter, with smooth internal surface and condensate removal system.

The MG Dryer metallization was carried out through a special process that results in higher surface hardness, very low porosity, and excellent superficial finish (super finishing). The new MG Dryer is producing high quality glossy paper.

Increased Operational Safety

Targeting to increase the operator safety, the machine now has a complete system of walkways and ladders, that allows access to the machine's maintenance and set up points, within the highest safety standards and in accordance with customer's requirements.

The threading system now features ropeless threading at strategic points.

HERGEN/IRANI

It is an enormous satisfaction for HERGEN to reap the rewards of this serious and competent work, carried out in close partnership with IRANI.

The excellent results of this modernization, obtained in such a short time, would not have been possible without the excellent cooperation of IRANI professionals, who spared no efforts to make this project a great success.

Our thanks to all professionals involved.