INPEL acquires NEW Tissue Machine

INSIDE the INNOVATION

November 24, 2021

GUAPI PAPÉIS boosts PM1 complete modernization

February 1, 2022

Santo Antônio de Pádua, RJ, Brazil

INPEL acquires new Tissue Machine

In order to increase its product portfolio as well as improve production and quality, INPEL will replace its MP2 with a new SMART ECO tissue machine.

The project is part of the company's investment plan that reaches up to 25 million reais.

Quality increase and portfolio boost

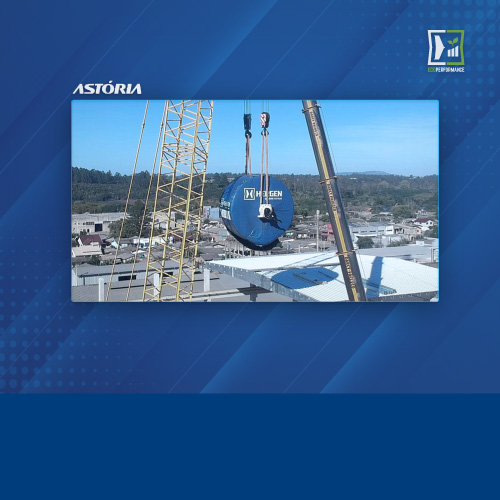

The SMART ECO - supplied by HERGEN - is equipped with a Crescent Former model SMART HCF-920, which will enable the production of high quality double-ply tissue.

The Crescent Former improves the paper web formation, the CM profile and the softness of the sheet, it enables the machine speed increase, besides saving energy, clothing and fibers.

Production with low energy consumption

The SMART ECO enables – thanks to its Yankee Cylinder's increased drying capacity – the paper production with low energy consumption. Fabricated in carbon steel and featuring a ribbed internal surface, the Smart Yankee Dryer Cylinders allow greater heat exchange thus, greater drying efficiency.

The machine was designed to work with a Canopy Hood, which targets simply extracting the water vapor generated by the paper drying process. The Hood uses two small fans, with very low energy consumption.

This configuration enables to get the maximum performance from the paper machine.

Some basic features

Production: 50 t/d double ply tissue (14 g/m²) / 65 t/d towel paper (22 g/m²)

Sheet width at Pope Reel: up to 2760 mm

iNOVA FLOW Hydraulic Head Box

HCF 920 Crescent Former

Yankee Dryer Ø 3,660 mm, fabricate in carbon steel with ribbed internal surface

Pneumatic Pope Reel with Column type shaft puller

HERGEN/INPEL partnership

HERGEN wishes INPEL success on this new project and appreciates the opportunity to take part in this important step for the company.

HERGEN TISSUE MACHINE

High-performance Tissue Machines up to 2,200 m/min

Drying and pressing concepts that deliver excellent cost effectiveness per ton of paper produced.

Flexible designs that allow for gradual upgrades starting from a basic model.

Proven engineering experience, with customized solutions that allow achieving performance very quickly and safely.