Start Up of a new Tail Treading and Sheet Stabilizing System

Start up of a Tissue Machine rebuild at Manikraft Guaianazes

May 15, 2017

Hergen delivers a new Hydraulic Headbox

September 7, 2017Reduction of paper losses and improvement on machine runnability

May 2017

Santa Maria Cia. de Papel e Celulose – PM#2

Guarapuava, Paraná, Brazil

Installation targets

Improves machine stability, decreasing the quantity of sheet brakes at Central Roll outlet

Enables the speed increase of the paper machine and as a consequence a higher production level

Reduce the operator intervention on machine, providing a safer tail treading operation

Project data

Grade: writing and printing from 45 to 90 g/m²

Raw material: virgin pulp

Machine speed: 800 m/min

Scope of supply

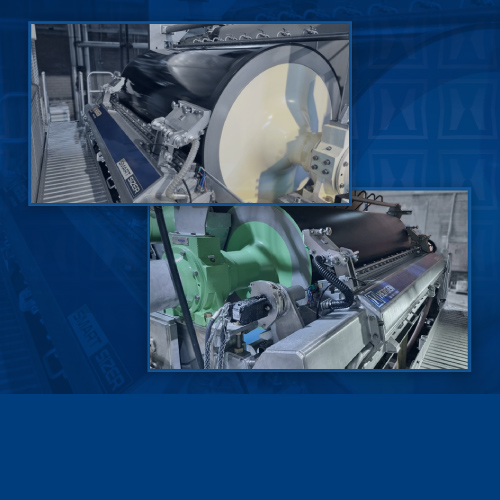

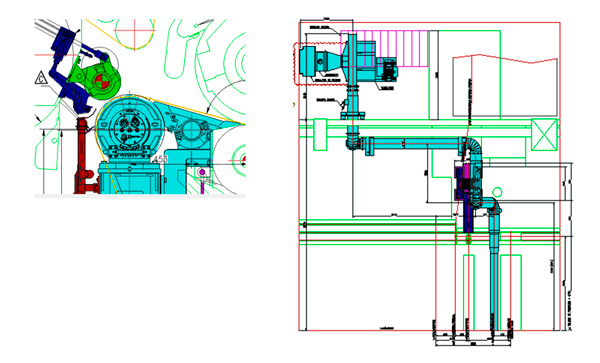

Installation of a Transfer Suction Roll

Installation of a Sheet Stabilizing Box

New Couch Pit Chute

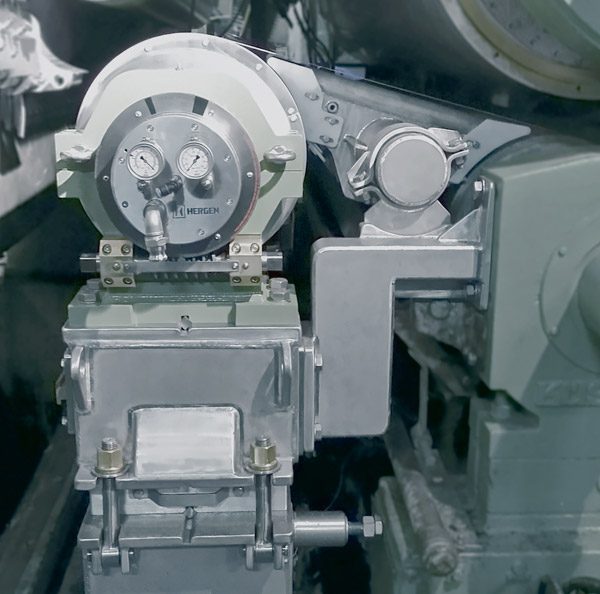

Roll doctor equipped with a air shower

Stabilizing Box Fan

Results

The system worked very well, improving the sheet transfer efficiency between the 2nd and 3rd Presses.

Watch the way the system works on the video below.