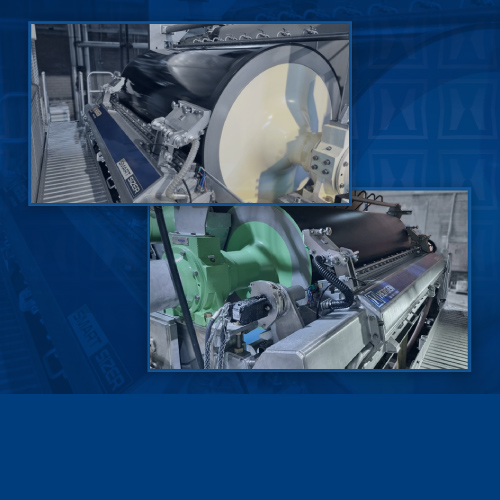

Delivery of SMART STEEL DRYER Cylinders

HERGEN renews its ASME Certification

October 28, 2020

HERGEN concludes delivery of the new OL PAPÉIS Tissue Machine

November 27, 2020Dryer Cylinders

HERGEN has just supplied new Smart Steel Dryer Drying Cylinders to the national market.

The many advantages of the steel construction

Drying gain

The main steel property is ductility and this allows the reduction of the shell thickness of the dryer cylinder resulting in higher rates for heating transfer from the steam to the paper web.

Increase safety

ZERO risk of explosion due to construction in steel.

Reduce maintenance

Excellent welding process applied for steel plates eliminating possible leakages.

Increase useful width

Due to the compact construction of the steel dryer cylinders, it increases its useful width eliminating wet edge problems during paper drying.

Quality control

Quality certificate for all steel plates used in the manufacturing – mechanical and chemical properties.

Quality certificate for cast elements – mechanical and chemical properties and metallographic structure.

Cylinder construction in compliance with strict manufacturing standards (ASME, PED or others, as required).

Ultrasonic inspection for every shell and cover plate.

Dimensional inspection after shell manufacturing.

Ultrasonic inspection for all welding seams.

Thermal treatment for stress relief.

Hydrostatic test in compliance with ASME and PED standards.

Dynamic balancing as per ISO 1940 class G 2.5 Standard.

Thorough dimensional control in all stages of cylinder manufacturing.