INCAPE has registered positive results after PM modernization

HERGEN will be at TISSUE SUMMIT 2022

March 16, 2022

HERGEN solutions at Tissue World Miami and Tissue Summit 2022

May 3, 2022

Another big step for INCAPE

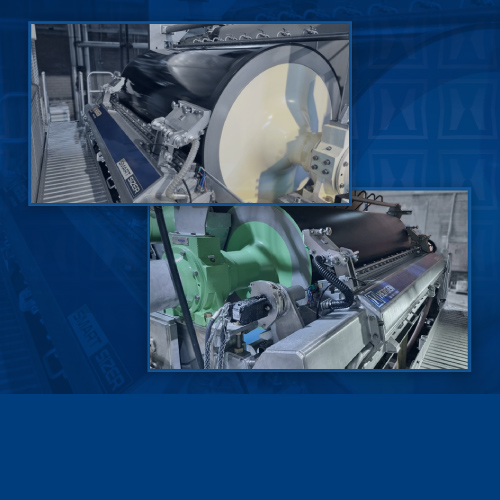

By the end of January, INCAPE started its PM modernization. The project – supplied by HERGEN – was a great success and the machine has been producing sellable paper since first day.

The drying section is brand new. The steel fabricated drying cylinders feature a higher heat transfer to the paper, resulting in production increase.

The machine now has a new tail threading system, from the press section until the pope reel, which reduces losses and increases the efficiency of the paper machine.

The project also includes a new pope reel, with extended rails and a jumbo roll weighing station.

Safety Increase

The project attests to INCAPE's commitment to safety.

The new drying cylinders are safer than the cast iron ones as they feature zero risk of explosion.

The threading system increases significantly the safety of the paper machine operation team.

The entire machine now has physical safeguards with locked gates, which allow access only to authorized personal.

Quality and Production Increase

After PM modernization, the profile and strength of the paper sheet have improved significantly, which is very important for the converting lines.

The machine has also registered production increase, allowing INCAPE to meet its growing demand.

HERGEN/INCAPE

HERGEN is grateful for the partnership and congratulates INCAPE for its constant development, based on investments in quality and technology, environmental awareness and respect for people.