Novacki’s PM2 Modernization on a fast pace

START-UP – New Tissue Paper Machine at DAMAPEL

June 7, 2022

AVELINO BRAGAGNOLO will install a new Headbox on its PM2

August 15, 2022

Novacki's PM2 modernization is in full progress. The new Drying Group and the new Rewinder has already been installed and earlier this month the new Size Press started-up.

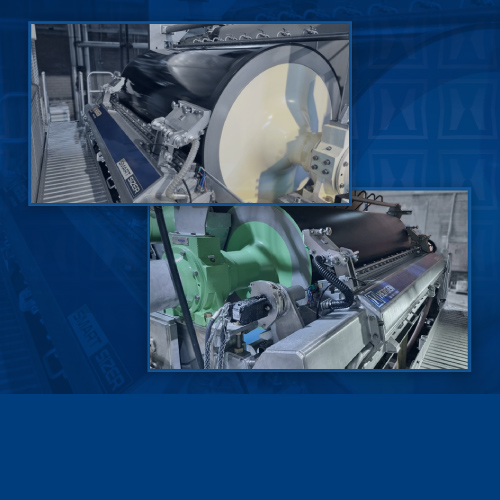

Rewinder

The new Rewinder has been running since May.

The installation was needed to meet the increase in production, due to the PM2 upgrade. The model supplied is an Excel 2.5, with a working speed of 2,500 m/min equipped with a regenerative brake. The diameter on the unwinding stand is 2650 mm. The entire project complies with the strictest Safety Standards.

The new Rewinder has produced compact rolls, with excellent formation. In addition, thanks to the regenerative break it features a very low energy consumption.

Size Press

With the objective of increasing the physical tests of the paper, the new Size Press went into operation on August.

The size press features 1.500 mm diameter applicator rolls, which increases the quality of starch application. The Size Press frame is entirely built in Stainless Steel, increasing the equipment's lifespan, and reducing maintenance costs.

The design foresees the future installation of Starch Application Headers, i.e., the equipment is ready to be converted into a film press.

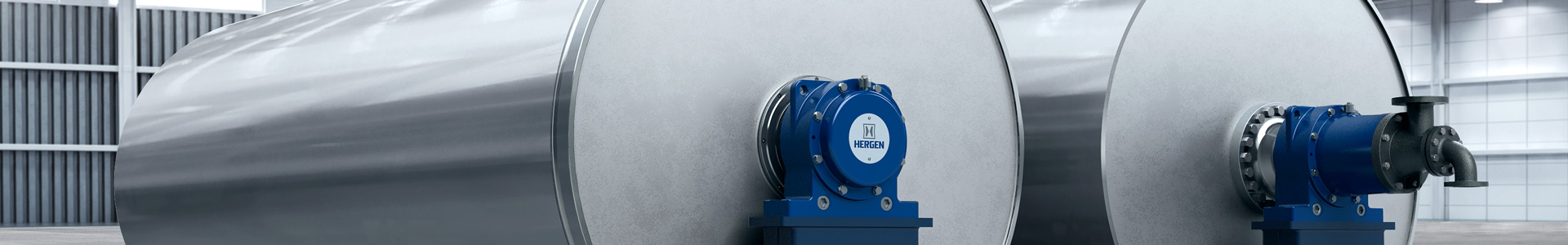

HERGEN - Paper and Board Machines

Forming Sections

Complete sections with primary and secondary fourdriniers

Headboxes with pulsation attenuators

Frameworks are fully Stainless Steel cladding

Dryer Cylinders

Made of Steel (increased efficiency and reduced costs)

With ASME Certification

With Turbulence bars and thermal insulation

Metering Size for Starch Application

Fiber saving

Improvement in physical tests

Drying energy savings

Starch film application with up to 14% solid content

Rewinders

Fully automated, with regenerative brake, automatic sheet threading,

application Header, transversal knife, carton core feeder

Equipped with all necessary devices to ensure operator safety