Delivery of a new MG Dryer to IRANI

HERGEN solutions at Tissue World Miami and Tissue Summit 2022

May 3, 2022

START-UP – New Tissue Paper Machine at PAPELERA REYES, Peru

May 31, 2022

IRANI Papel e Embalagem

Vargem Bonita, SC, Brazil

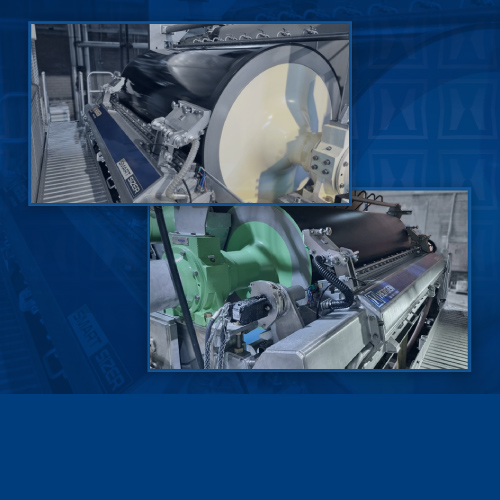

On the last May 11th, HERGEN has delivered a new MG Dryer to IRANI, which will replace the old PM2 Cast Iron Dryer.

This delivery is part of a rebuild package for the PM2 that also includes a complete replacement of the existing Drying Section, a new Pope Reel, a new Lumpbreaker Roll and upgrades of the existing Fourdrinier, Press Section and Rewinder.

Cylinder Data:

Diameter: 4,200 mm

Face Length: 2,950 mm

Heads bolted to Cylinder Body

Machined inner surface, ensuring perfect heat transfer

With hybrid condensate collectors (for low and high speed)

Working pressure: 6 bar

High performance with energy saving

Paper production consumes a lot of energy. In a Tissue paper machine, the drying process is responsible for about 70% of the machine's energy consumption. This means that a more efficient drying system results directly in significant energy savings.

Hergen Smart Yankee Dryer is made of Steel. Due to the mechanical properties of this material, its thickness can be significantly less than the ones made of Cast Iron, increasing the heat transfer by up to 35%, resulting in lower energy consumption for the same production.

Hergen quality

NO rupture risk due construction in carbon steel

Increase production: HIGHER HEAT TRANSFER UP TO 35% AS COMPARED WITH CAST IRON CYLINDERS resulting in higher paper evaporation ratio

Innovative condensate extraction system

Higher reliability with no risk inherent to the casting process, such as porosities or discontinuities

Two construction options for Head Covers: mounted with capscrew or welded to the cylinder shell

Metal surface with high hardness resulting in better creping quality

Excellent temperature profile

Steel plate material allows cylinders construction with any required diameter

Easy transportation: journals may be transported disassembled thus reducing the maximum load height